Powertrain Management GEN III V8 – Service Operations Page 6C3-3–1

Page 6C3-3–1

Section 6C3-3

Powertrain Management GEN III V8 –

Service Operations

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................4

1.1 General Description............................................................................................................................................... 4

1.2 Service Precautions and Notes ............................................................................................................................ 5

2 General Service Operations..................................................................................................................6

2.1 Service Operations Not Covered in This Section................................................................................................ 6

Fuel System............................................................................................................................................................ 6

Engine Dress Covers............................................................................................................................................. 6

2.2 Fuel Injector Coil Test ........................................................................................................................................... 7

Engine Coolant T emperature Between 10 – 35°C ............................................................................................. 7

Engine Coolant Temperature Outside 10 – 35°C............................................................................................... 8

2.3 Fuel Injector Balance Test .................................................................................................................................. 10

Fuel Injector Balance Test – With Tech 2 .......................................................................................................... 10

Fuel Injector Balance Test – Without Tech 2..................................................................................................... 10

Fuel Injector Pressure Drop Calculation........................................................................................................... 12

Fuel Injector Pressure Drop Analysis............................................................................................................... 12

2.4 Fuel Injector Leak Down Test ............................................................................................................................. 13

2.5 Power Balance Test............................................................................................................................................. 14

3 Component Replacement....................................................................................................................15

3.1 Components Not Covered In This Section........................................................................................................ 15

Air-conditioning System ..................................................................................................................................... 15

Electrical Components........................................................................................................................................ 15

Fuel System.......................................................................................................................................................... 15

Transmission – Automatic.................................................................................................................................. 15

Transmission – Manual ....................................................................................................................................... 15

3.2 Accelerator Pedal Position Sensor .................................................................................................................... 16

Remove................................................................................................................................................................. 16

Reinstall................................................................................................................................................................ 16

3.3 Accelerator Pedal Position Sensor Support Bracket ........................................................................................ 17

Remove................................................................................................................................................................. 17

Reinstall................................................................................................................................................................ 17

3.4 Air Cleaner Assembly.......................................................................................................................................... 18

Air Cleaner Upper Housing................................................................................................................................. 18

Remove............................................................................................................................................................ 18

Reinstall ........................................................................................................................................................... 18

Air Cleaner Lower Housing Assembly............................................................................................................... 19

Remove............................................................................................................................................................ 19

Reinstall ........................................................................................................................................................... 19

3.5 Camshaft Position Sensor .................................................................................................................................. 20

Remove................................................................................................................................................................. 20

Reinstall................................................................................................................................................................ 20

Techline

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–2

Page 6C3-3–2

3.6 Crankshaft Position Sensor................................................................................................................................ 21

Remove................................................................................................................................................................. 21

Reinstall................................................................................................................................................................ 21

3.7 Engine Coolant Temperature Sensor................................................................................................................. 22

Remove................................................................................................................................................................. 22

Test ....................................................................................................................................................................... 23

Resistance Check ............................................................................................................................................ 23

Reinstall................................................................................................................................................................ 24

3.8 Engine Oil Pressure Sensor................................................................................................................................ 25

Remove................................................................................................................................................................. 25

Reinstall................................................................................................................................................................ 25

3.9 EVAP Canister Purge Solenoid Valve ................................................................................................................ 26

Remove................................................................................................................................................................. 26

Test ....................................................................................................................................................................... 26

Resistance Check ............................................................................................................................................ 26

Functional Test................................................................................................................................................. 27

Reinstall................................................................................................................................................................ 27

3.10 Fuel Pulse Dampener .......................................................................................................................................... 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 28

3.11 Fuel Rail Assembly.............................................................................................................................................. 29

Remove................................................................................................................................................................. 29

Disassemble......................................................................................................................................................... 30

Fuel Injector Assembly..................................................................................................................................... 30

Reinstall................................................................................................................................................................ 32

3.12 Heated Oxygen Sensor........................................................................................................................................ 33

Service Precautions............................................................................................................................................. 33

Remove................................................................................................................................................................. 33

Test ....................................................................................................................................................................... 34

Heater Resistance Check................................................................................................................................. 34

Reinstall................................................................................................................................................................ 34

3.13 Ignition Coil Assembly........................................................................................................................................ 35

Remove................................................................................................................................................................. 35

Test ....................................................................................................................................................................... 36

Reinstall................................................................................................................................................................ 36

3.14 Intake Air Temperature Sensor........................................................................................................................... 37

Test ....................................................................................................................................................................... 37

Resistance Check ............................................................................................................................................ 37

3.15 Knock Sensor....................................................................................................................................................... 38

Remove................................................................................................................................................................. 38

Reinstall................................................................................................................................................................ 38

3.16 Manifold Absolute Pressure Sensor .................................................................................................................. 39

Remove................................................................................................................................................................. 39

Reinstall................................................................................................................................................................ 39

3.17 Mass Air Flow Sensor and Intake Air Duct........................................................................................................ 40

Remove................................................................................................................................................................. 40

Reinstall................................................................................................................................................................ 41

3.18 Powertrain Control Module................................................................................................................................. 42

Remove................................................................................................................................................................. 42

Reinstall................................................................................................................................................................ 43

3.19 Powertrain Control Module Bracket Assembly................................................................................................. 44

Remove................................................................................................................................................................. 44

Reinstall................................................................................................................................................................ 44

3.20 Schrader Valve – Fuel Pressure Test Point....................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 45

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–3

Page 6C3-3–3

3.21 Spark Plugs.......................................................................................................................................................... 46

Service Precautions............................................................................................................................................. 46

Remove................................................................................................................................................................. 46

Clean, Inspect and Adjust................................................................................................................................... 47

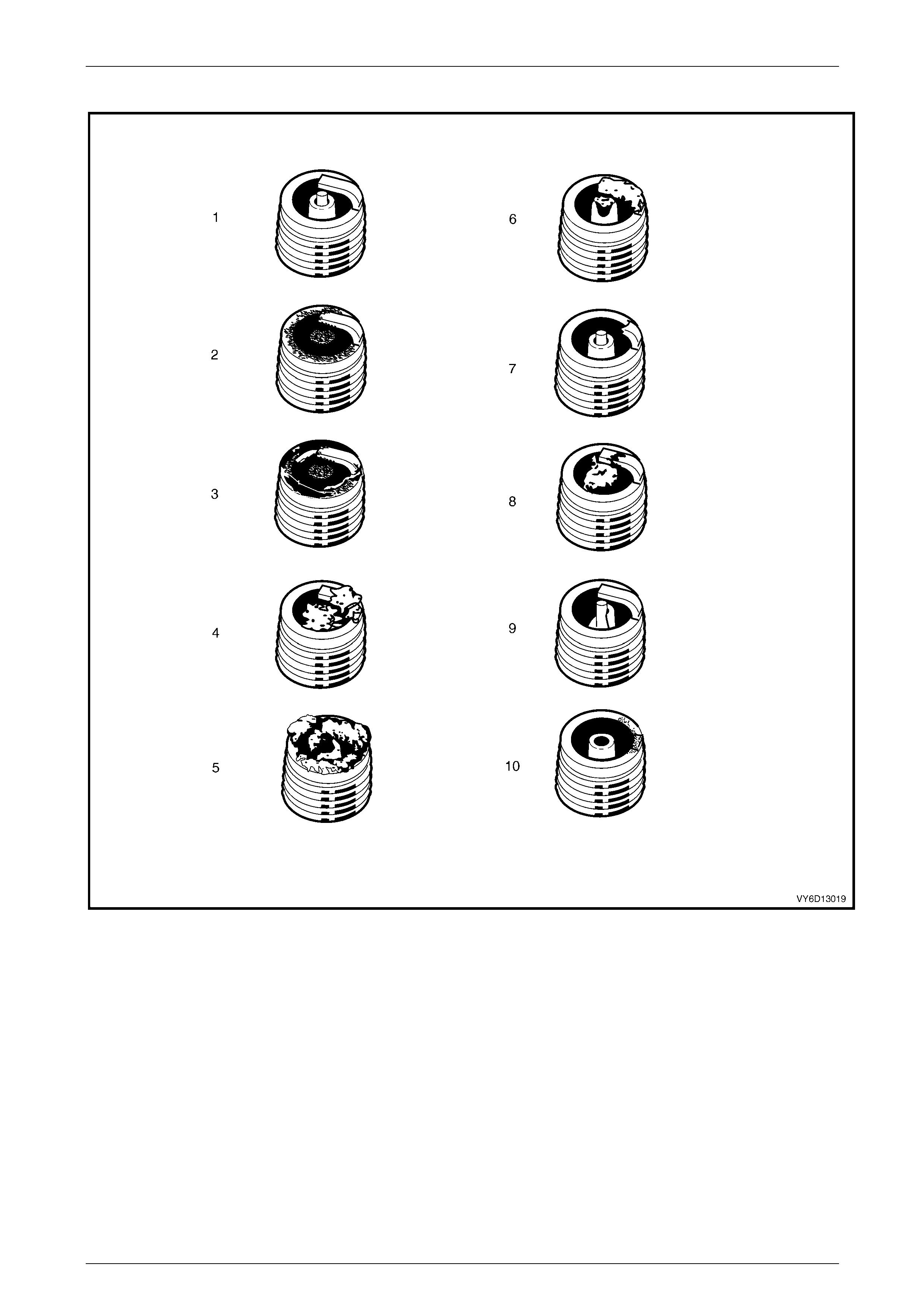

Spark Plug Inspection ......................................................................................................................................... 47

Poor Spark Plug Performance.......................................................................................................................... 47

Analysis of Spark Plug Condition ..................................................................................................................... 49

Reinstall................................................................................................................................................................ 51

3.22 Spark Plug Leads................................................................................................................................................. 52

Remove................................................................................................................................................................. 52

Inspect .................................................................................................................................................................. 52

Reinstall................................................................................................................................................................ 52

3.23 Throttle Actuator Control Module....................................................................................................................... 53

Remove................................................................................................................................................................. 53

Reinstall................................................................................................................................................................ 53

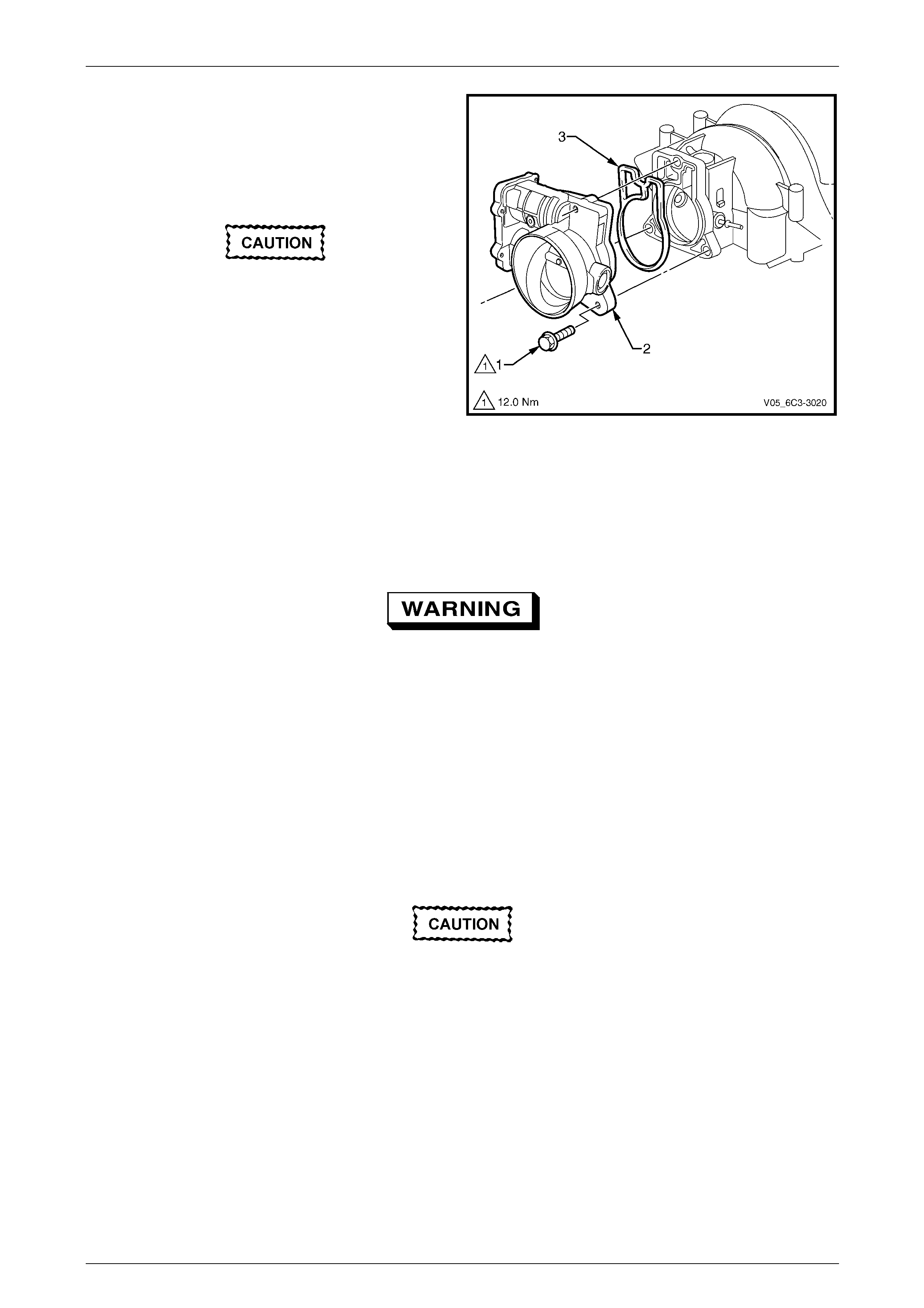

3.24 Throttle Body Assembly...................................................................................................................................... 54

Handling Precautions.......................................................................................................................................... 54

Remove................................................................................................................................................................. 54

Inspect .................................................................................................................................................................. 55

Reinstall................................................................................................................................................................ 56

4 Specifications.......................................................................................................................................57

5 Torque Wrench Specifications............................................................................................................59

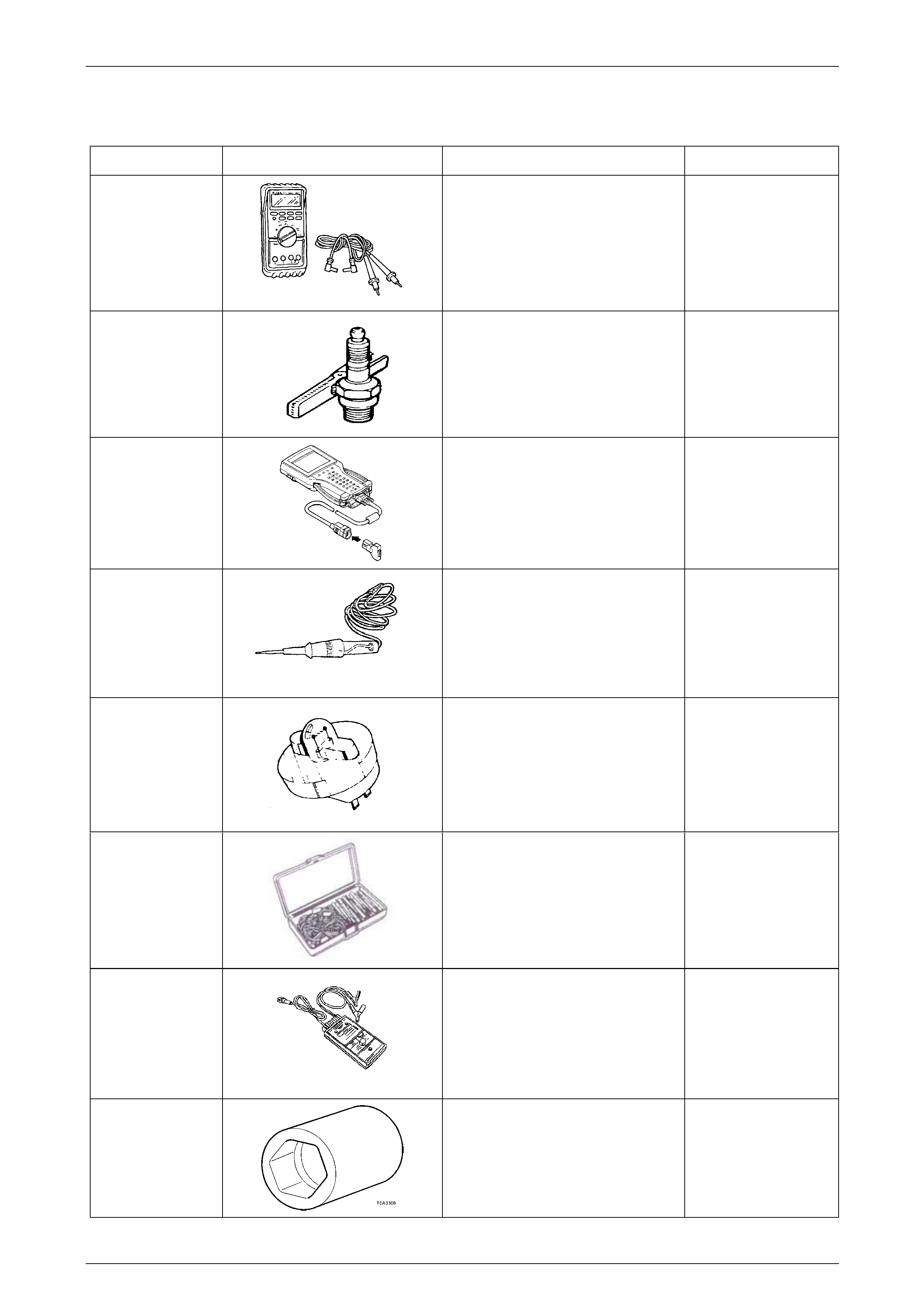

6 Special Tools ........................................................................................................................................60

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–4

Page 6C3-3–4

1 General Information

1.1 General Description

This Section describes the correct service procedures to repair components of the powertrain management system used

with the GEN III V8 engine. Emphasis is placed on the proper procedures and repair of components related to this

specific system.

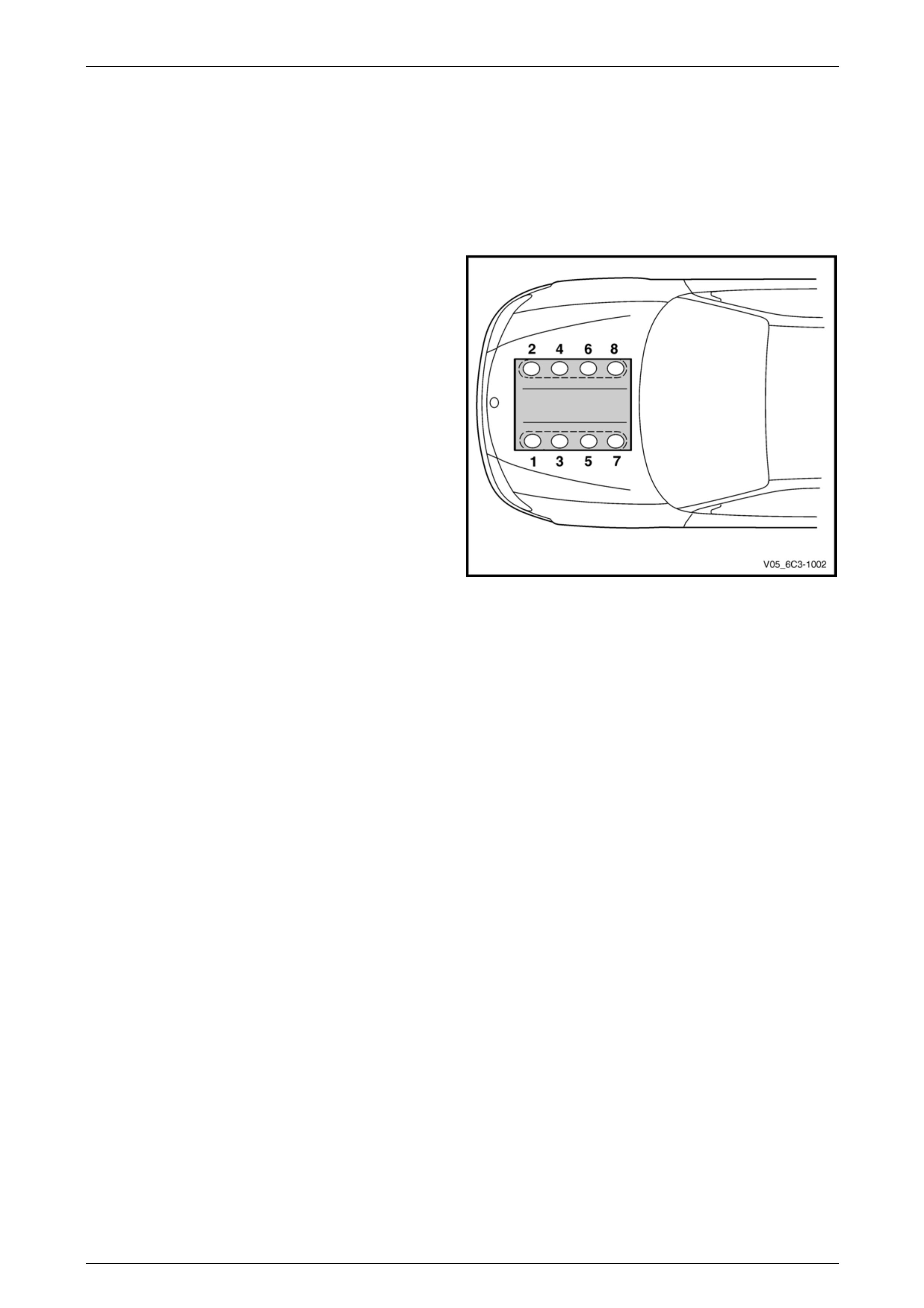

Engine cylinder identification follows the international

standard OBD II. This standard calls for the engine cylinder

bank number one to be identified by the location of cylinder

number one. Therefore the numbering for the GEN III V8

engine is:

• 1, 3, 5, 7 – Left-hand side (Bank 1),

• 2, 4, 6, 8 – Right-hand side (Bank 2).

The engine firing order is 1, 8, 7, 2, 6, 5, 4, 3.

Figure 6C3-3 – 1

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–5

Page 6C3-3–5

1.2 Service Precautions and Notes

When servicing the po wertrain management system, failure to follow the safety and precautionary directions can lead to

personal injury and/or improper system operation:

• If working on a vehicle which has been sub jected to an under bonnet thermal incident (fire), wear appropriate

protective clothing to prevent personal injury. Components that contain fluoro-elastomer may produce a corrosive

bi-product when subjected to extreme heat.

• Disconnection of the battery affects certain vehicle electronic systems.

Refer to Section 00 Warnings, Cautio ns and Notes before disconnecting the battery.

• Prior to disconnection or removal of any components associated with the fuel system, clean the area around any

connection points to avoid possible contamination of the fuel system.

• A depressurised fuel system contains residual fuel that can be spilled during service operations. To reduce the

chance of personal injury, cover the fittings with a shop towel to absorb any fuel spillage prior to performing the

service operation. Once the service operation has been completed, place the towel in an approved container for

disposal.

• To avoid accidental fuel discharge, it is advisable to disconnect the battery and remove the fuel pum p relay if the

fuel line between the fuel pump and the fuel rail is to be disconnected/open for an indefinite period.

• Always tighten fasteners to the correct tightening torque, and where indicated in the service proce dure, follow the

correct tightening sequence, precautions and recommendations to prevent premature failure of the fastener or

component, refer to Section 00 Warnings, Cautions and No tes for further information on fasteners.

• Do not use silicone based assembly lubricants as damage to the heated oxygen sensors may result.

• After completing the required service operations, road test the vehicle to ensure correct powertrain management

system operation.

• Before removing the PCM, disconnect the ba ttery ground lead.

• Never start the engine without the battery being securely connected.

• Never disconnect the battery while the engine is running or when charging the battery.

• Never touch the connector pins of any electronic component, such as a PCM, as electrostatic discharge (ESD)

damage may result. For further information, refer to Section 00 Warnings, Cautions and Notes .

• Never subject the PCM to temperatures below -40°C and above 125°C.

• Ensure that all cable harness plugs are connected securely and that battery termin als are thoroughly cle an.

• The powertrain management system harness connectors are designed to fit only one way; there are indexing tabs

and slots on both halves of the connector. Forcing the connector into place is not necessary if it is being installed

with the correct orientation. Failure to take care to match the indexing tabs and slots correctly can cause damage to

the connector, the module, or other vehicle components or systems.

• Never connect or disconnect a cable harness plug at the PCM, or fuel system component when the ignition is

switched on.

• Before attempting any electric welding on the vehicle, disconnect the battery leads and the PCM connectors.

• When steam or high pressure cleaning the engine, do not direct the cleaning nozzle at the PCM or other powertrain

management system components. If this happens, corrosion of the terminals can occur.

Use of incorrect electrical test equipment

when performing the powertrain management

service procedures could result in incorrect

results or damage to PCM system

components.

• Use only the test equipment specified in the diagnostic tables, since other test equipment may

either give incorrect results or damage servic eable components,

refer to Section 6C3-2 Powertrain Management – GEN III V8 – Diag nostics.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–6

Page 6C3-3–6

2 General Service Operations

2.1 Service Operations Not Covered in This

Section

There are cases where service operations used by the powertrain management system are covered in other Sections of

the service documentation. To aid technicians in locating the necessary service procedures, refer to the following

references.

Fuel System

For the following fuel system service procedures, refer to Section 8A1 Fuel System:

• fuel system cleaning,

• fuel system leak and pressure test,

• fuel feed hose to fuel rail replacement, and

• fuel line quick connect fittings.

Engine Dress Covers

For service procedures of the engine dress covers, refer to Section 6A3 Engine Mechanical – GEN III V8.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–7

Page 6C3-3–7

2.2 Fuel Injector Coil Test

1 Depressurise the fuel system, refer to Section 8A1 Fuel System.

2 Turn the ignition off.

3 Remove the engine dress cover, refer to Section 6A3 Engine Mechanical – GEN III V8.

4 Using Tech 2, observe the engine coolant temperature (ECT), refer to Section 0C Tech 2. If the ECT is between

10 – 35°C, refer to Engine Coolant T emperature Between 10 – 35°C, or if the ECT is outside this range, refer to

Engine Coolant Temperature Outside 10 – 35°C.

Engine Coolant Temperature Between 10 – 35°C

Step Action Value(s) Yes No

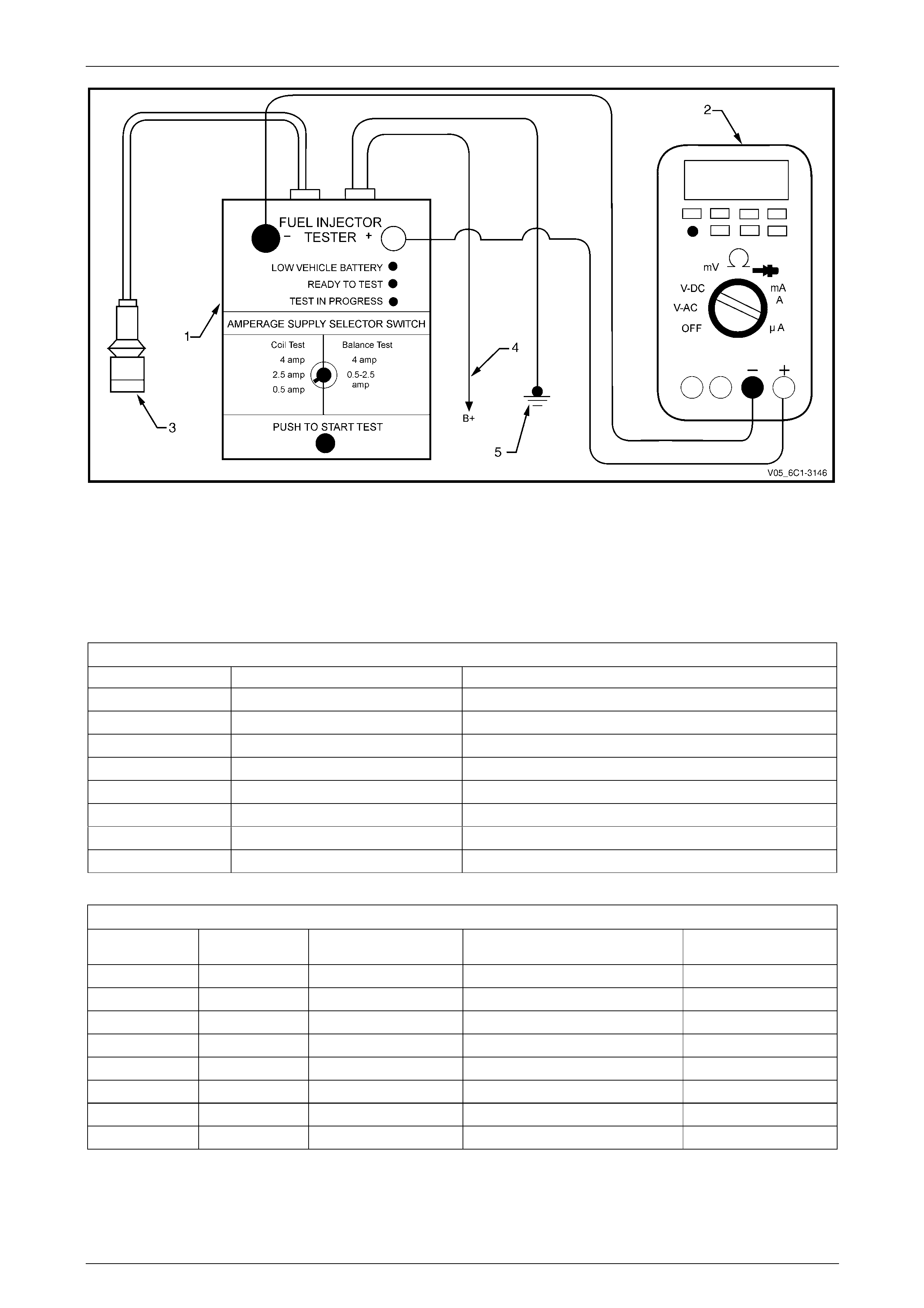

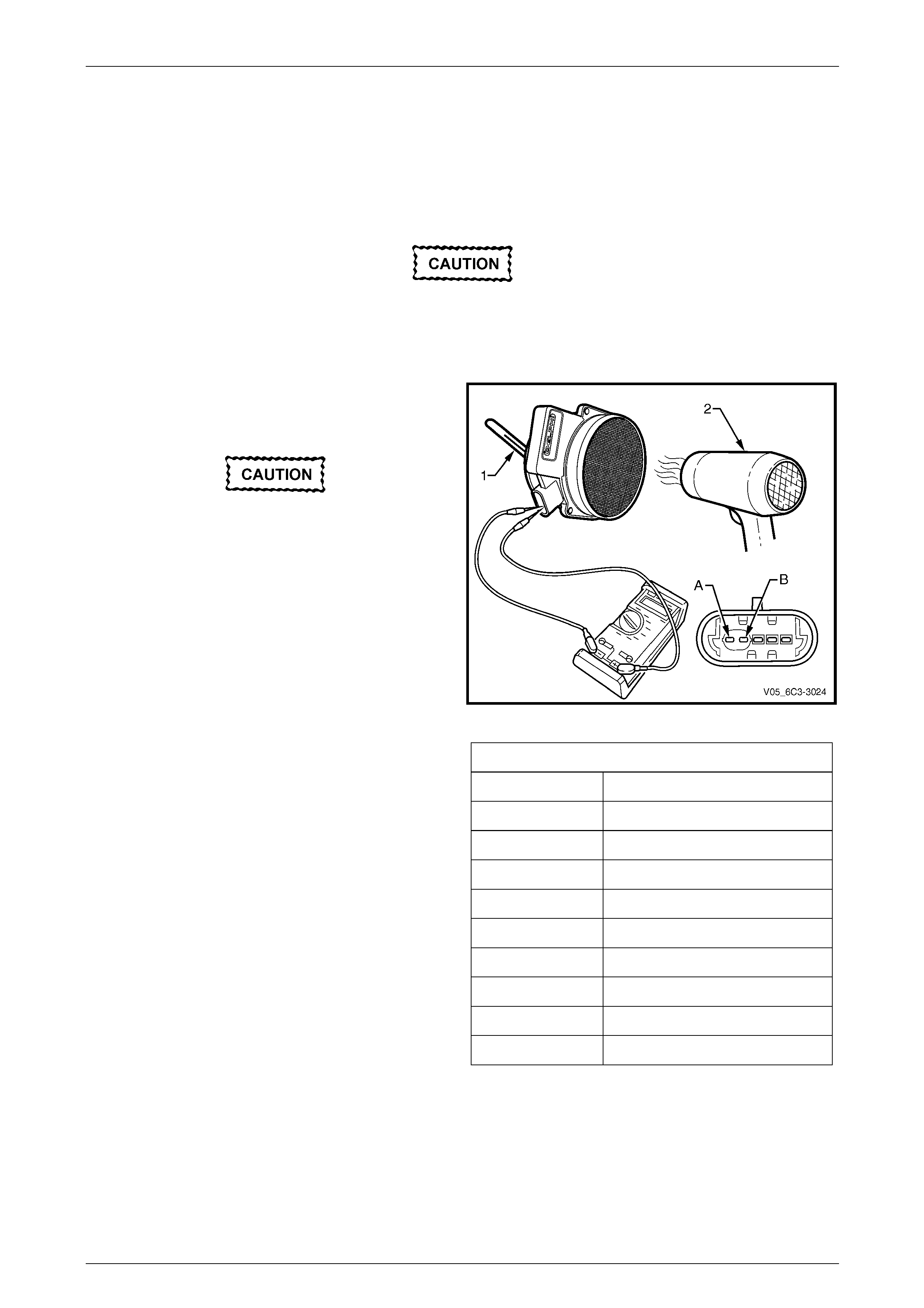

1 1 Set the amperage supply selector switch on the

fuel injector coil/balance tester (1), special tool

J 39021 to the Coil Test 0.5 Amp position. Refer

to Figure 6C3-3 – 2.

2 Connect the fuel injector tester leads (4 and 5) to

B+ and ground.

3 Connect the digital multimeter (2) positive a nd

negative lead to the fuel injector tester. Set the

multimeter to read DC Voltage.

4 Connect the fuel injector tester to a fuel injector.

5 Press the Push to Start Test button on the fuel

injector tester.

6 Observe and record the voltage reading on the

digital multimeter.

NOTE

The voltage reading ma y ris e during the test.

Record the voltage reading after one secon d

of the test.

7 Repeat steps 4 through 6 for each fuel injector.

NOTE

The table in Figure 6C3-3 – 3 shows an

example of the results from a fuel injector

coil test.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilise), or

voltage readings outside of the specified value? 5.5 – 6.6 V

Replace the faulty

fuel injector/s. Refer

to 3.11 Fuel Rail

Assembly System OK

When all repairs are comp leted, check the system for fuel leaks and correct operation .

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–8

Page 6C3-3–8

Engine Coolant Temperature Outside 10 – 35°C

Step Action Value(s) Yes No

1 1 Set the amperage supply selector switch on the

fuel injector coil/balance tester (1), special tool

J 39021 to the Coil Test 0.5 Amp position. Refer

to Figure 6C3-3 – 2.

2 Connect the fuel injector tester leads (4 and 5) to

B+ and ground.

3 Connect the digital multimeter (2) positive a nd

negative lead to the fuel injector tester. Set the

multimeter to read DC Voltage.

4 Connect the fuel injector tester to a fuel injector.

5 Press the Push to Start Test button on the fuel

injector tester.

6 Observe and record the voltage reading on the

digital multimeter.

NOTE

The voltage reading ma y ris e during the test.

Record the voltage reading after one secon d

of the test.

7 Repeat steps 4 through 6 for each fuel injector.

8 Identify the highest voltage reading recorded from

the six fuel injectors tested that is 9.5 V or below.

NOTE

Disregard those voltage readings that are

above 9.5 V. Voltage readings above 9.5 V

indicate a faulty fuel injector.

9 Subtract the remaining voltage readings recorded

in Step 8, from the highest voltage reading.

Are any of the values recorded in Step 9 greater than

the specified value? 0.6 V Go to Step 2 System OK

2 Replace any fuel injector that had any of the following:

• a subtracted value exceeding 0.6 V,

• an initial reading above 9.5 V, and

• an erratic reading.

NOTE

The table in Figure 6C3-3 – 4 shows an

example of the results from a fuel injector

coil test.

Has the repair been completed? – System OK. –

When all repairs are comp leted, check the system for fuel leaks and correct operation .

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–9

Page 6C3-3–9

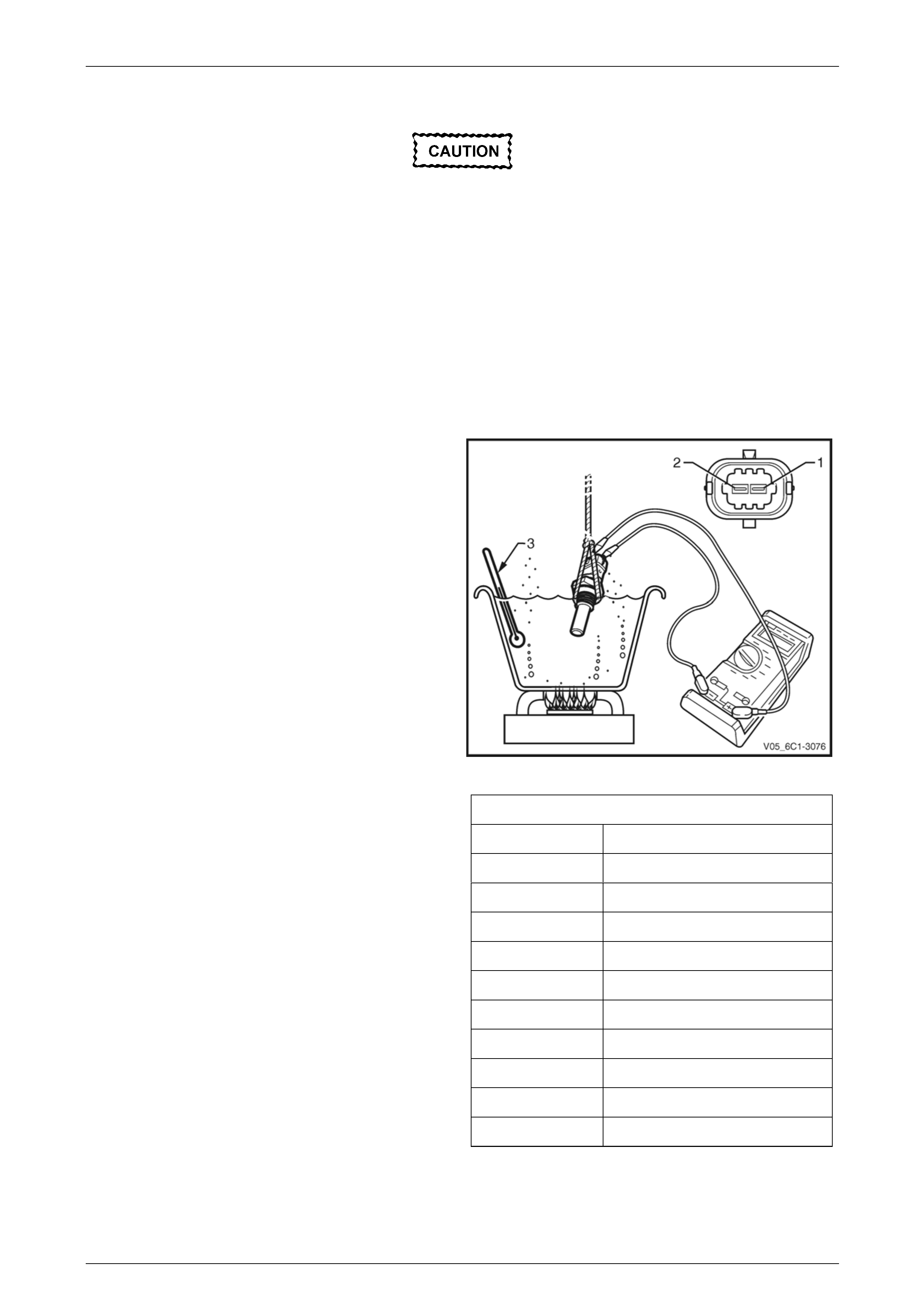

Figure 6C3-3 – 2

Legend

1 Fuel Injector Coil/Balance Tester – Special Tool J39021

2 Digital Multimeter

3 Fuel Injector Harness Connector

4 To Battery Positive Terminal

5 Battery Earth

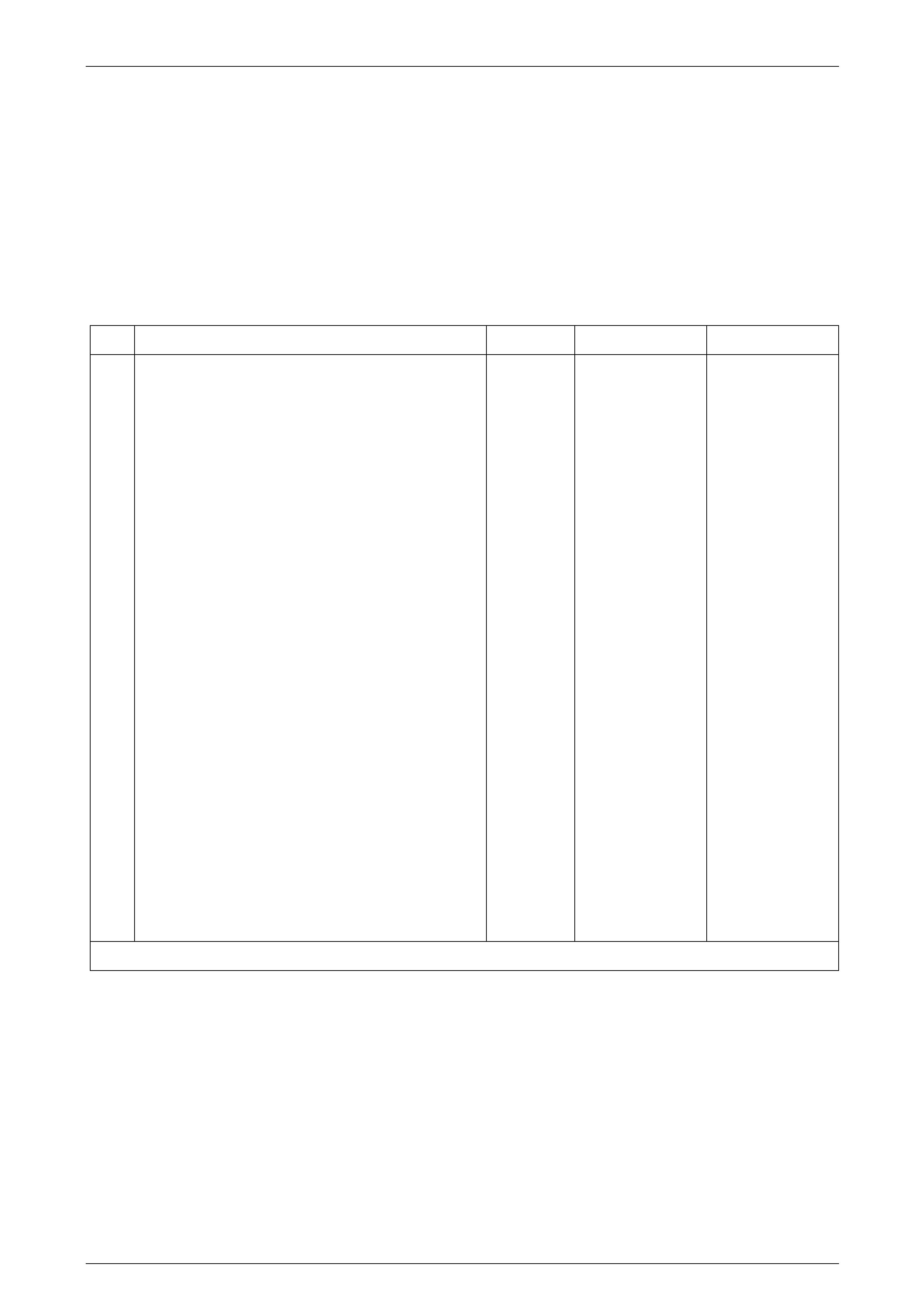

Fuel Injector Coil Test Example – Engine Coolant Temperature b etween 10 – 35°C (Typical Values Shown)

Fuel Injector No. Voltage Reading Pass / Fail (acceptable range 5.5 - 6.6V)

1 6.6 Pass

2 5.4 Fail

3 6.2 Pass

4 6.1 Pass

5 6.7 Fail

6 6.0 Pass

7 6.2 Pass

8 6.7 Fail

Figure 6C3-3 – 3

Fuel Injector Coil Test Exampl e – En gine Coolant Temperature Above / Below 10 – 35°C (Typical Values Shown)

Fuel Injector No. Voltage Reading Highest Voltage Reading

(9.5V or less) Subtracted Value

(acceptable voltage 0.6 V) Pass / Fail

1 9.8 – –

Fail

2 6.4 7.0 0.6 Pass

3 6.9 7.0 0.1 Pass

4 5.8 7.0 1.2 Fail

5 7.0 7.0 0.0 Pass

6 6.3 7.0 0.7 Fail

7 6.9 7.0 0.1 Pass

8 6.4 7.0 0.6 Pass

Figure 6C3-3 – 4

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–10

Page 6C3-3–10

2.3 Fuel Injector Balance Test

To avoid irregular fuel pressure readings, do

not perform this procedure if the engine

coolant temperature is above 94°C.

Fuel Injector Balance Test – With Tech 2

1 Check the engine coolant temperature is below 94°C.

2 Perform the fuel injector coil test and replace any fuel inj ectors that are not functioning correctly before proceeding.

Refer to 2.2 Fuel Injector Coil Test.

3 Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with

the fuel injector balance test. Refer to Section 8A1 Fuel Sys t em.

4 While the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel s ystem.

Refer to Section 8A1 Fuel System.

5 When the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel press ure gauge.

NOTE

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

6 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

7 On Tech 2 select Engine / V8 GEN III / Actuator Test / Fuel Injector Balance.

8 Follow the Tech 2 prompts, recording the fue l pressure gauge reading for each injector.

NOTE

The fuel pressure readings taken in Step 8 are

known as the second pressure read ing

9 Perform the Fuel Injector Pressure Drop Calculati on is this Section.

Fuel Injector Balance Test – Without Tech 2

1 Check the engine coolant temperature is below 94°C.

2 Perform the fuel injector coil test and replace any fuel inj ectors that are not functioning correctly before proceeding.

Refer to 2.2 Fuel Injector Coil Test.

3 Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with

the fuel injector balance test. Refer to Section 8A1 Fuel Sys t em.

4 While the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel s ystem.

Refer to Section 8A1 Fuel System.

5 When the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel press ure gauge.

NOTE

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

6 Remove the engine dress covers, refer to Section 6A3, Engine Mech anical – GEN III V8.

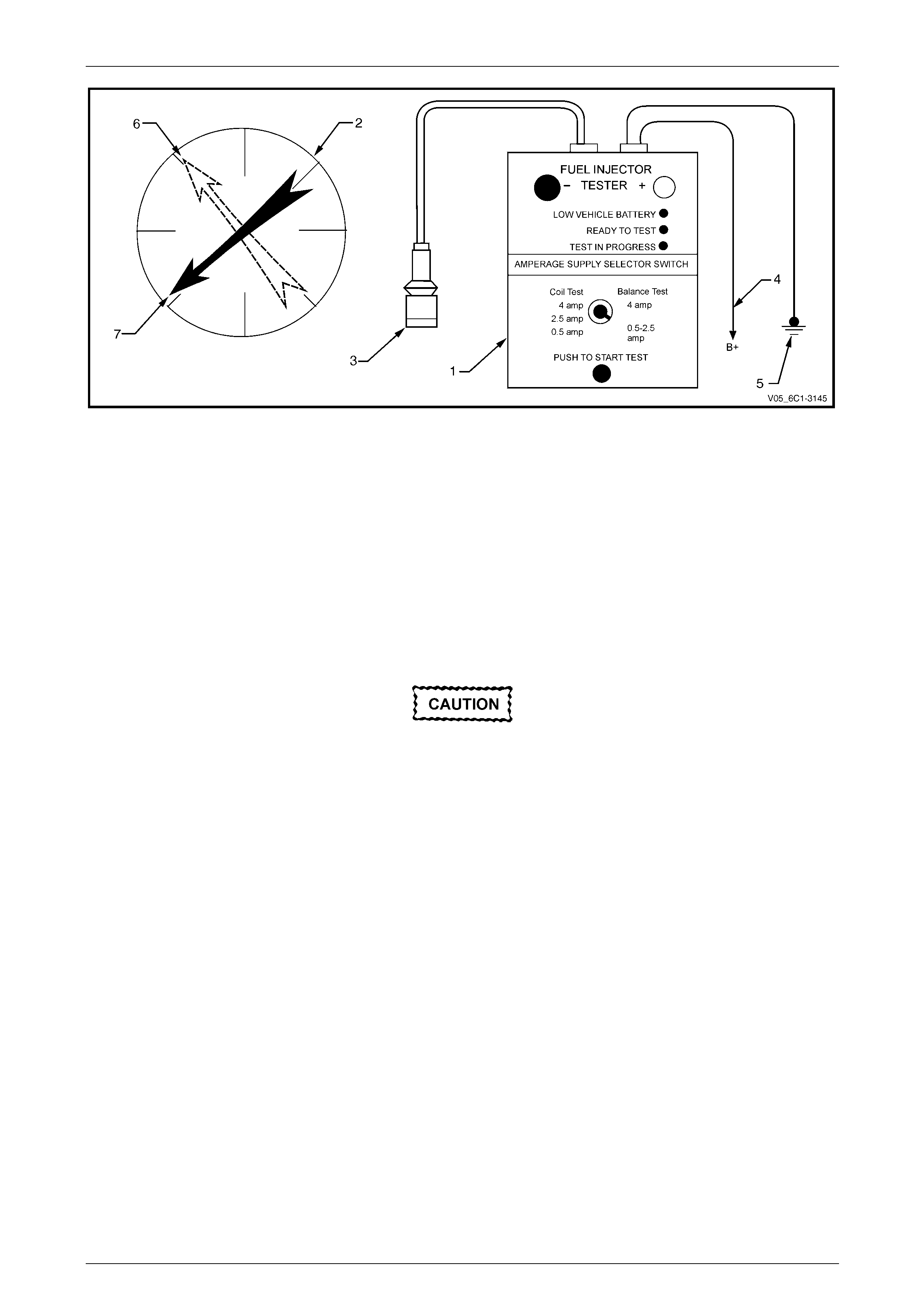

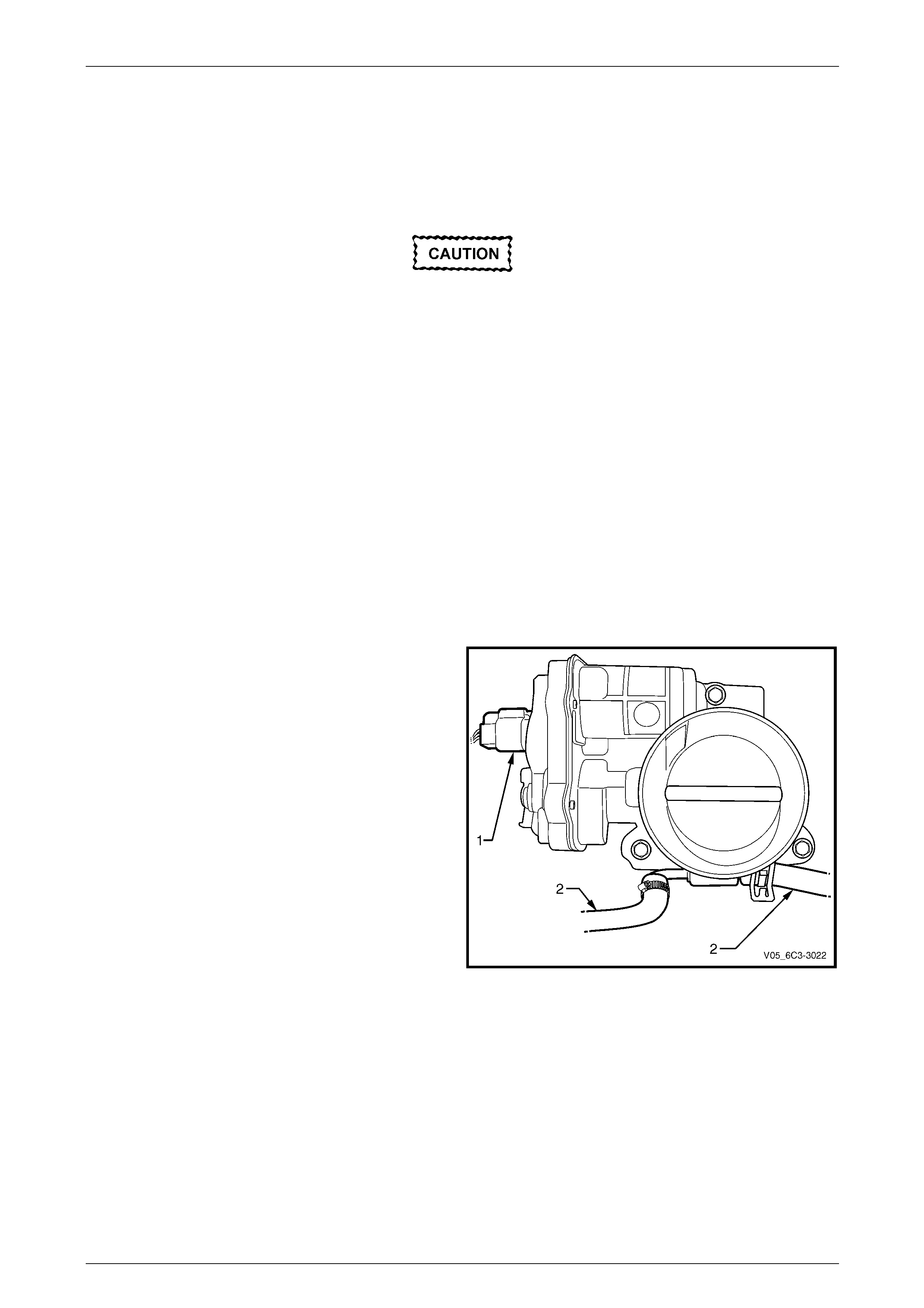

7 Connect Tool No. J 39021 fuel injector coil/balance tester (1), to the fuel injector connector.

Refer to Figure 6C3-3 – 5.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–11

Page 6C3-3–11

Figure 6C3-3 – 5

Legend

1 Fuel Injector Coil/Balance Tester – Special Tool J39021

2 Fuel Pressure Gauge – Special Tool SD28018

3 Fuel Injector Harness Connector

4 To Battery Positive Terminal

5 Battery Earth

6 First Pressure Reading

7 Second Pressure Reading

8 Connect the fuel injector tester battery positive lead (4) and battery negative lead (5) to the battery.

9 Set the amperage supply selector of the fuel injector tester to the Balance Test 0.5 – 2.5 amp position.

As the fuel pressure tends to increase after

the fuel injector stops fuel delivery, record the

fuel pressure value immediately after the fuel

injector stops fuel delivery. Do not record the

higher fuel pressure value.

10 Press the Push to Start Test Button on the fuel injector tester to activate the fuel injector.

11 Record the fuel pressure readi ng in dicated by the fuel pressure gaug e.

NOTE

The fuel pressure readings taken in Step 10 is

known as the second pressure read ing

12 Repeat the balance test press ure reading for each fuel injector.

13 Perform the Fuel Injector Pressure Drop Calculation is this Section.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–12

Page 6C3-3–12

Fuel Injector Pressure Drop Calculation

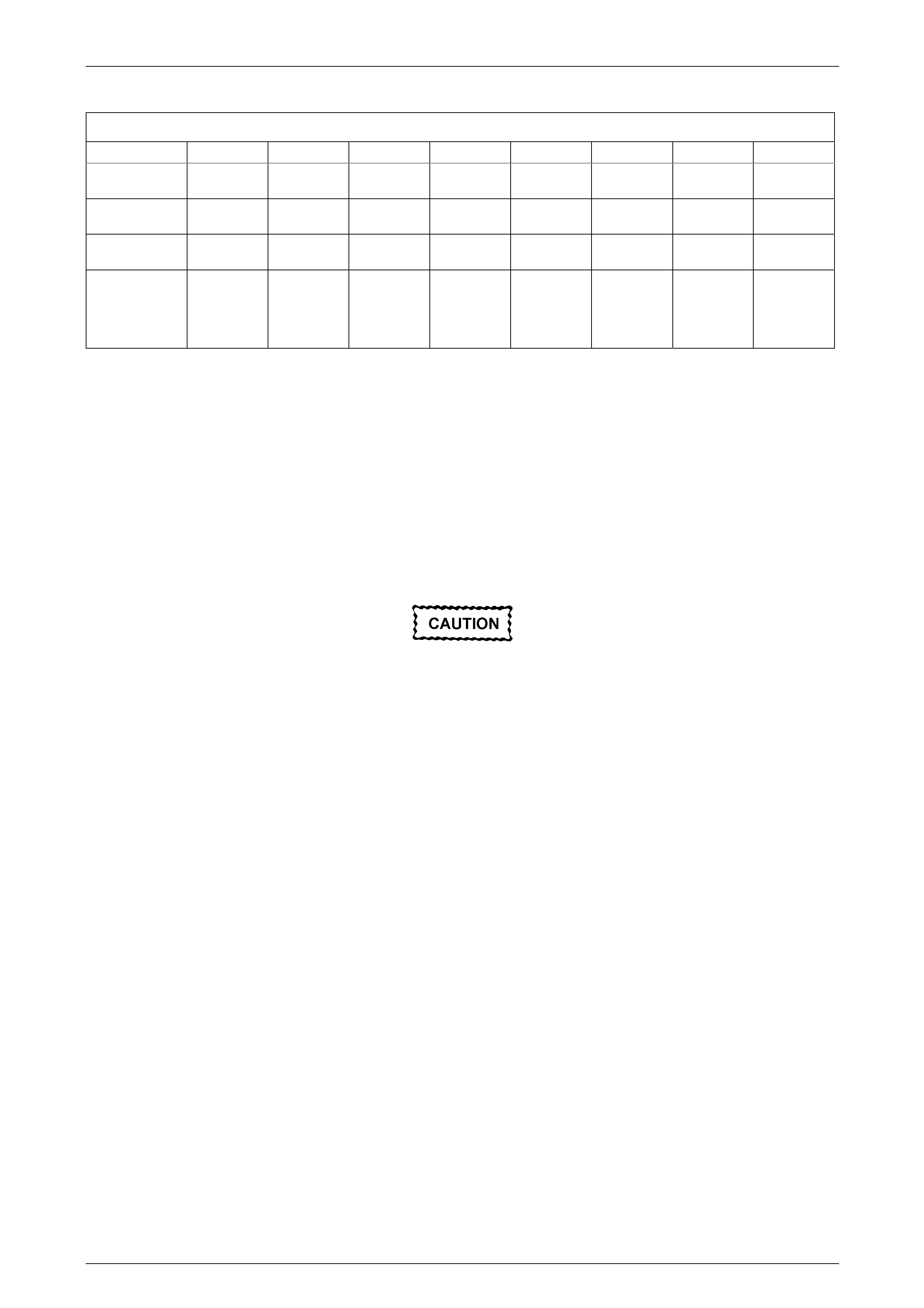

Fuel Injector Balance Test Example – Typical Values Sh own

Cylinder 1 2 3 4 5 6 7 8

1st Pressure

Reading 360 kPa 360 kPa 360 kPa 360 kPa 360 kPa 360 kPa 360 kPa 360 kPa

2nd Pressure

Reading 155 kPa 131 kPa 155 kPa 200 kPa 146 kPa 150 kPa 146 kPa 131 kPa

Amount of

Pressure Drop 205 kPa 229 kPa 205 kPa 160 kPa 214 kPa 210 kPa 214 kPa 229 kPa

Average

Range

198 - 218 kPa

Injector OK Replace

fuel injector

– to much

pressure

drop

Injector OK Replace

fuel injector

– to little

pressure

drop

Injector OK Injector OK Injector OK Replace

fuel injector

– to much

pressure

drop

Figure 6C3-3 – 6

a Subtract the second pressure reading from the first pressure reading to calculate the pressure drop value.

Refer to Figure 6C3-3 – 6, typical results.

b Calculate the pressure drop value for each fuel injector.

c Add all the individual pressure drop values of each fuel injector to calculate the total pressure drop.

d Divide the total pressure drop by the number of fuel injectors to calculate the average pr essure drop.

Fuel Injector Pressure Drop Analysis

a A fuel injector is faulty if its pressure drop va lue deviates from the average pressure drop by more than 1 0 kPa.

Do not repeat any portion of the test before

running the engine to prevent the engine from

flooding.

b Re-test any fuel injector that does not meet the specification.

c Replace all faulty fuel injectors, refer to 3.11 Fuel Rail Assembly.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–13

Page 6C3-3–13

2.4 Fuel Injector Leak Down Test

1 Turn the ignition switch off.

NOTE

Do not disconnect the fuel feed hose from the

fuel rail.

2 Remove the fuel rail assembly, refer to 3.11 Fuel Rail Assembly.

3 Lift up and support the fuel rail and injector assembly.

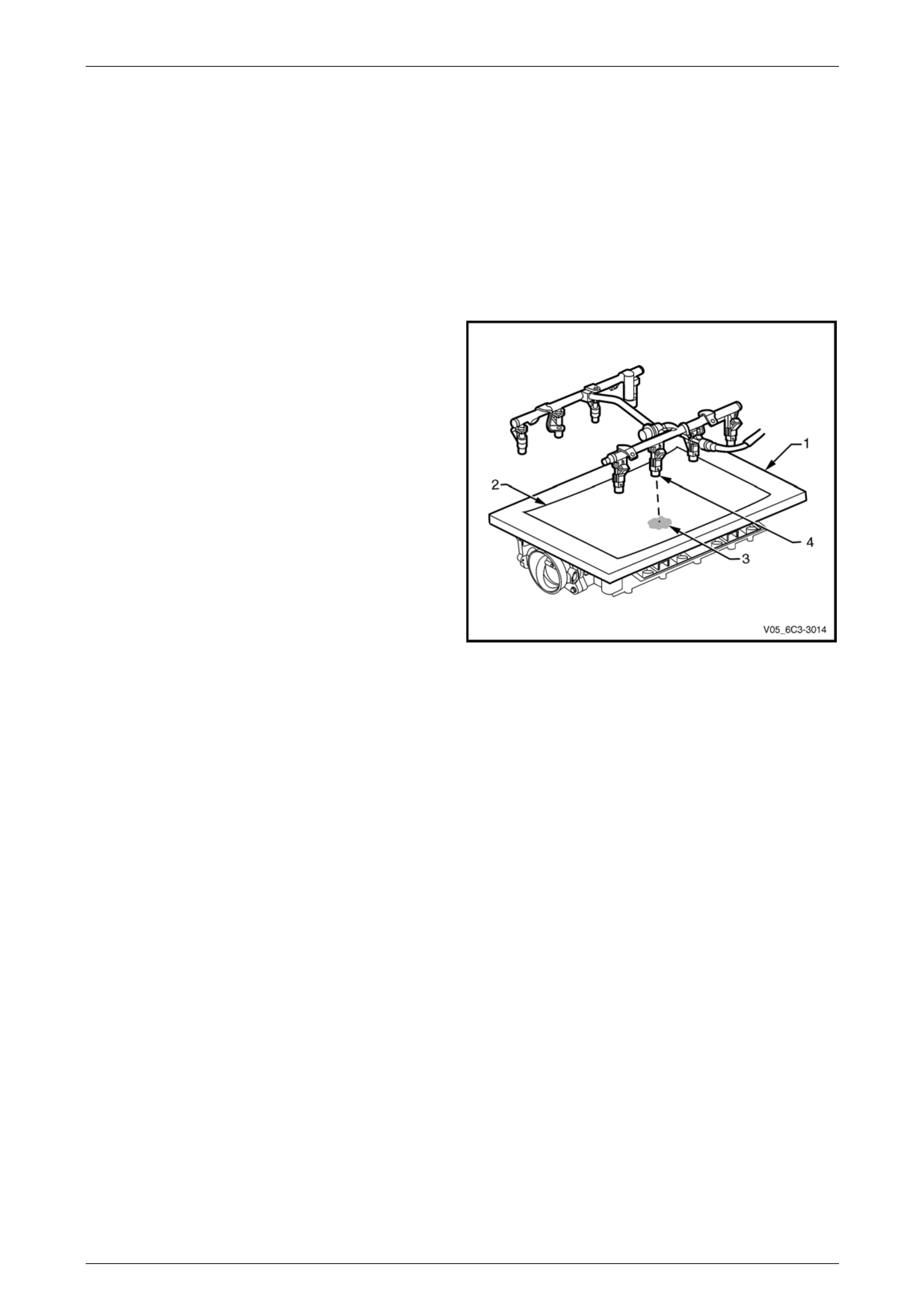

4 Place a board (1) with a sheet of clean paper (2),

preferably white, onto the intake manifold.

5 Using Tech 2, enable the fuel pump to pressurise the

fuel system. Refer to Section 0C Tech 2 for this

procedure.

6 Whilst the fuel system is pressurised, check the

following:

• Signs of fuel stains on the paper (3).

• Signs of weeping at the fuel injector spra y

tips (4).

7 If any of the above conditions are present, replace the

leaking fuel injector(s),

refer to 3.11 Fuel Rail Assembly.

8 Carefully reinstall the fuel rail assembly,

refer to 3.11 Fuel Rail Assembly.

9 Perform the following procedur e to inspect for fuel

leaks at the fuel rail:

a Turn the ignition switch on for two seconds.

Figure 6C3-3 – 7

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Inspect for fuel leaks at the fuel rail.

10 Road test the vehicle and check for correct operati on.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–14

Page 6C3-3–14

2.5 Power Balance Test

The power balance test is used to determine the condition of each cylinder. Once a problem cylinder(s) has been

identified, the cause of the fault – such as fuel, spark or a mechanical failure – must be rectified.

1 Turn the ignition switch off.

2 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

3 On Tech 2 select Engine / V8 GEN III / Function Tests / Power Balance.

4 Follow the Tech 2 prompts and perform the power balance test.

NOTE

• RPM readings displayed should be within 50

rpm of the idle speed for all cylinders.

• Any cylinder that does not cause a drop in

engine idle speed is misfiring.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–15

Page 6C3-3–15

3 Component Replacement

3.1 Components Not Covered In This

Section

There are cases where components use d b y the powertrain management system are covered in other Sections of the

service documentation. To aid technicians in locating the necessary service procedures for these components, refer to

the following references.

Air-conditioning System

For A/C pressure switch replacement procedure,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

Electrical Components

For the following electrical system component replacement procedures, refer to the appr opriate Sections as follows:

• Extended brake pedal trave l switch an d stop lamp switch service operations,

refer to Section 5A Service and Park Braking Systems.

• Fuse and relay locations, refer to Section 12O Fuses, Relays and Wiring Harnesses.

• Cruise control cancel switch and clutch start switch service operations, refer to Section 7A3 Clutch – GEN III V8.

• Cruise control switch assembly service operations, refer to Section 12E Cruise Control.

• Powertrain interface module PIM removal and installation procedure,

refer to Section 6E3 Powertrain Interface Module – GEN III V8 Engine.

• Neutral start and back-up lamp switch,

refer to Section 7C4 Automatic Transmission – 4L60-E – On-vehicle Servicing.

• Vehicle speed sensor service operations,

refer to Section 7C4 Automatic Transmission – 4L60-E – On-vehicle Servicing for autom atic transmission or

Section 7B2 Manual Transmission – GEN III V8 for manual transmission.

Fuel System

For the following fuel system component replacement procedures, refer to Section 8A1 F uel System:

• evaporative emission control canister,

• fuel filter,

• fuel hose/pipes layout,

• fuel pump motor assembly and fuel pressure regulator assembly,

• fuel sender assembly service operations, and

• fuel tank pressure sensor – Coupe only.

Transmission – Automatic

For automatic transmission sensors and compon ents,

refer to Section 7C4 Automatic Transmission – 4L60-E – On-vehicle Servicing.

Transmission – Manual

For manual transmission sensors and other components, refer to Section 7B2 Manual Transmission – GEN III V8 .

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–16

Page 6C3-3–16

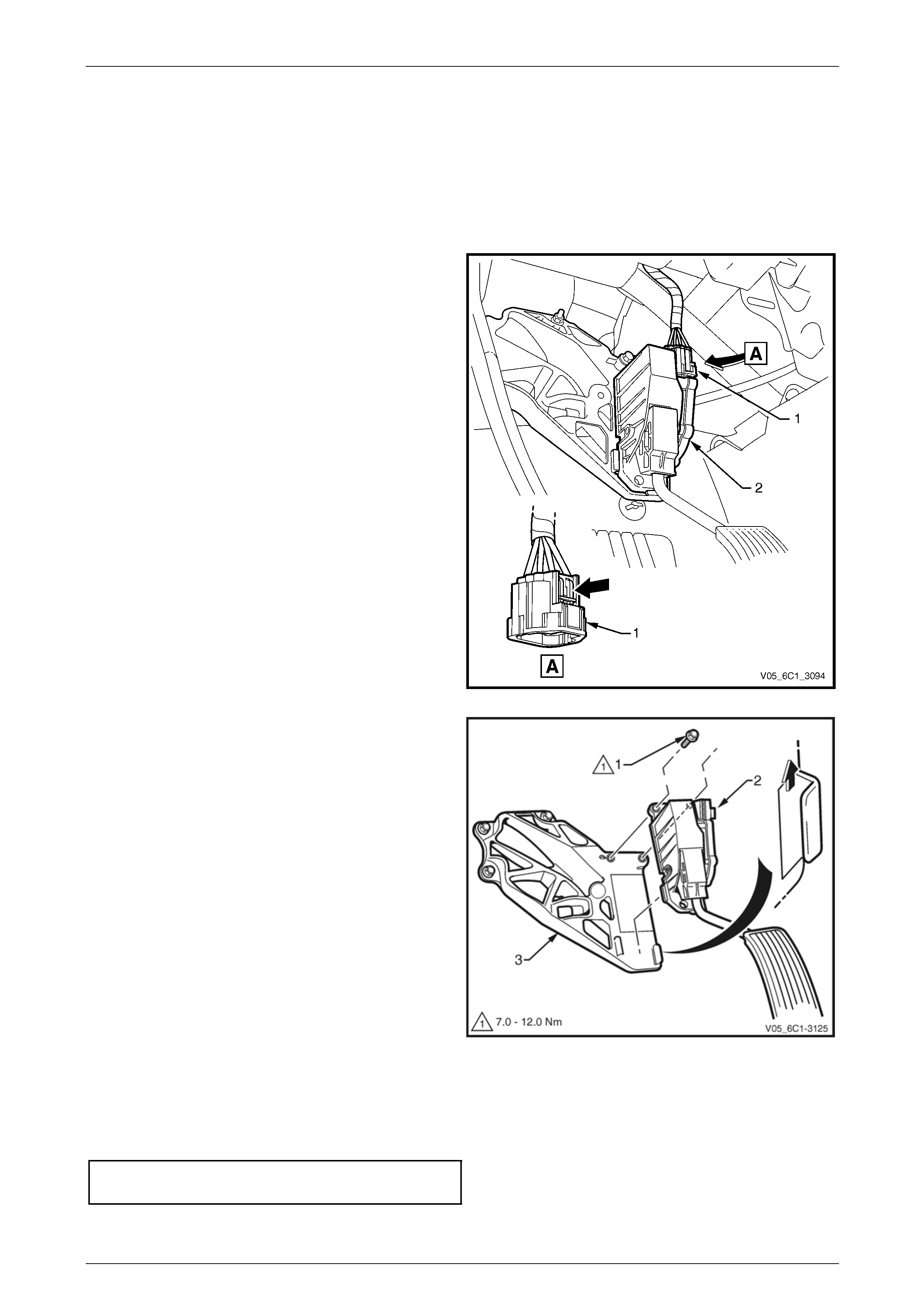

3.2 Accelerator Pedal Position Sensor

LT Section No. — 03–650

Remove

1 Turn the ignition switch off.

2 Remove the driver's side instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Consol e.

3 Disconnect the wiring connector (1) from the

accelerator pedal position (APP) sensor (2) by

depressing the latch in the direction of the ar row.

NOTE

If difficulty is experienced in disconnecting the

connector from the APP sensor, remove the

sensor from the accelerator pedal position (APP)

support bracket and then disconnect the

connector.

Figure 6C3-3 – 8

NOTE

If required, the APP sensor can be removed as

an assembly with the APP sensor support

bracket, refer to 3.3 Accelerator Pedal Position

Sensor Support Bracket.

4 Remove the bolt (1), two places, attaching the APP

sensor (2) to the APP sensor support bracket (3).

5 Slide the APP sensor upwards in the direction of the

arrow, to disengage the sensor from the support

bracket.

Figure 6C3-3 – 9

Reinstall

Reinstallation of the accelerator pedal position (APP) sensor is the reverse of the removal procedure, noting the

following:

1 Reinstall the bolts and tighten to the correct torque specification.

Accelerator pedal position sensor

attaching bolt torque specification.............7.0 – 12.0 Nm

2 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–17

Page 6C3-3–17

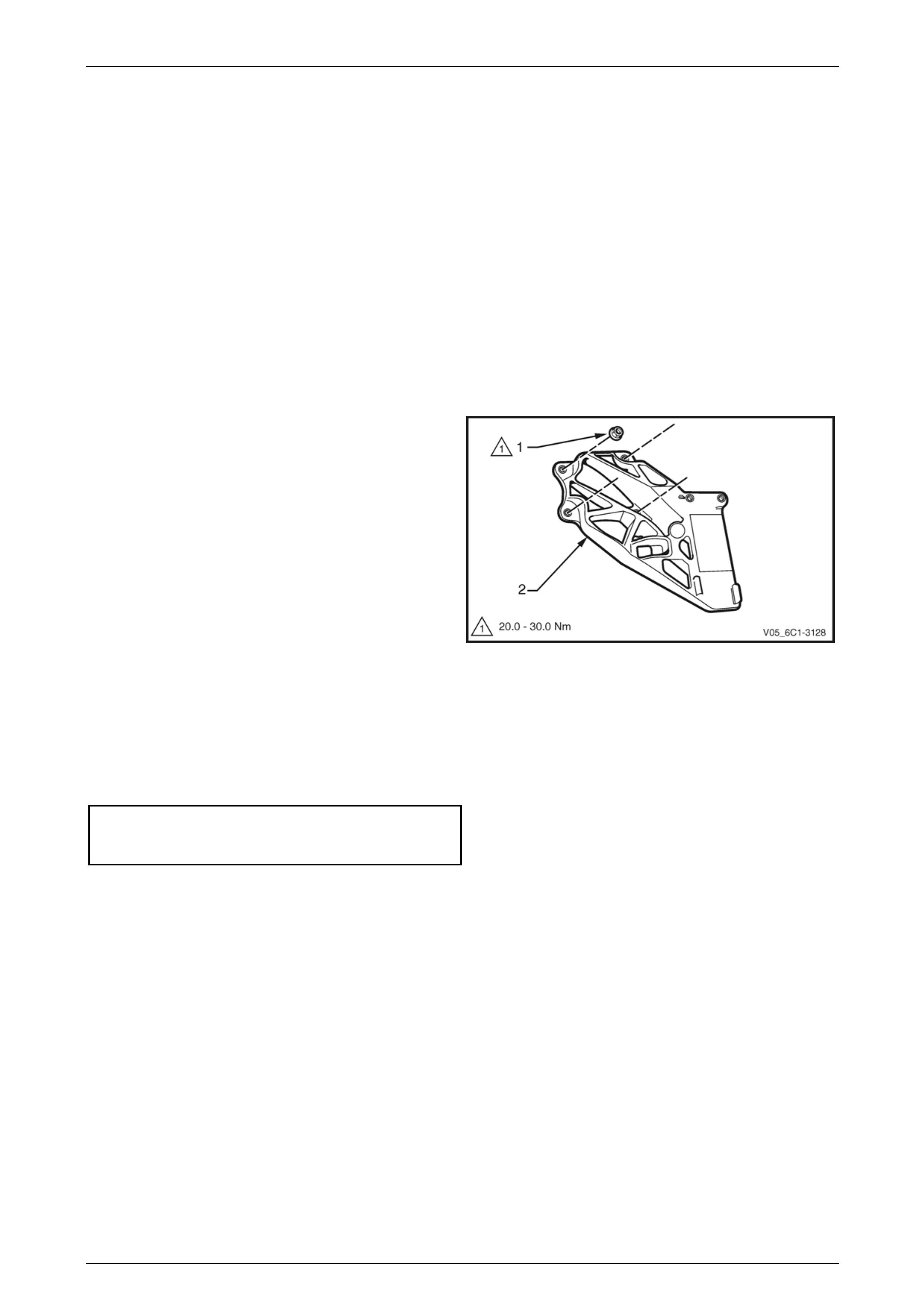

3.3 Accelerator Pedal Position Sensor

Support Bracket

LT Section No. — 03–650

Remove

1 Turn the ignition switch off.

NOTE

The accelerator pedal position (APP) sensor

support bracket may be remo ved as an assembly

with the accelerator pedal position APP sensor

attached.

2 If required, remove the APP sensor, refer to 3.2 Accelerator Pedal Position Sensor.

3 Remove the nut (1), four places, attaching the APP

sensor support bracket (2) to the dash panel and

remove the support bracket.

Figure 6C3-3 – 10

Reinstall

Reinstallation of the accelerator pedal position (APP) sensor support bracket is the reverse of the removal procedure,

noting the following:

1 Reinstall the nuts and tighten to the correct torque specification.

Accelerator pedal position (APP)

sensor support bracket attaching

nut torque specification...........................20.0 – 30.0 Nm

2 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–18

Page 6C3-3–18

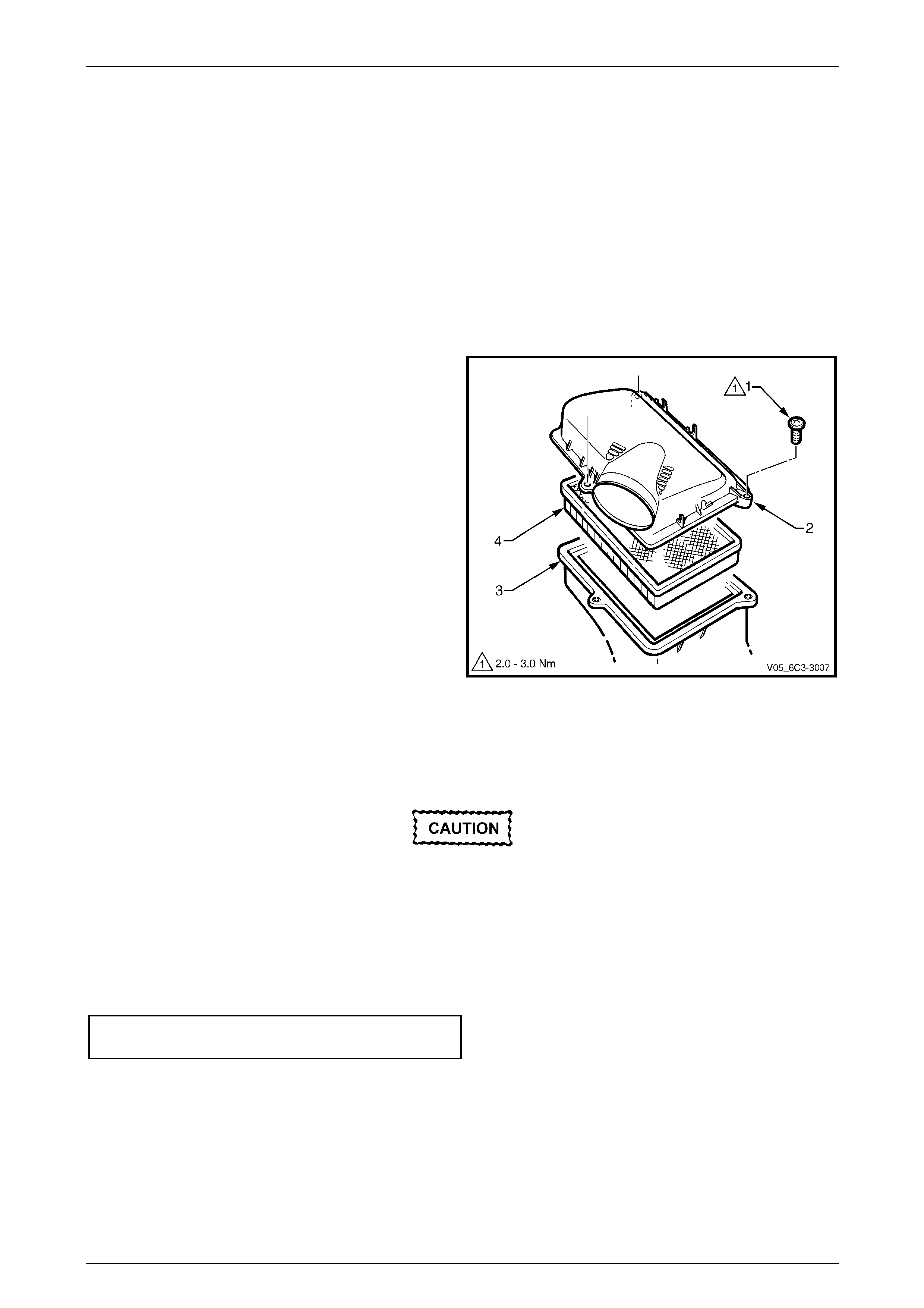

3.4 Air Cleaner Assembly

LT Section No. — 03–250

Air Cleaner Upper Housing

Remove

1 Turn the ignition switch off.

2 Remove the upper radiator shroud, refer to Section 6B3 Engine Cooling – GEN III V8.

3 Remove the intake air duct, refer to 3.17 Mass Air Flow Sensor and Intake Air Duct.

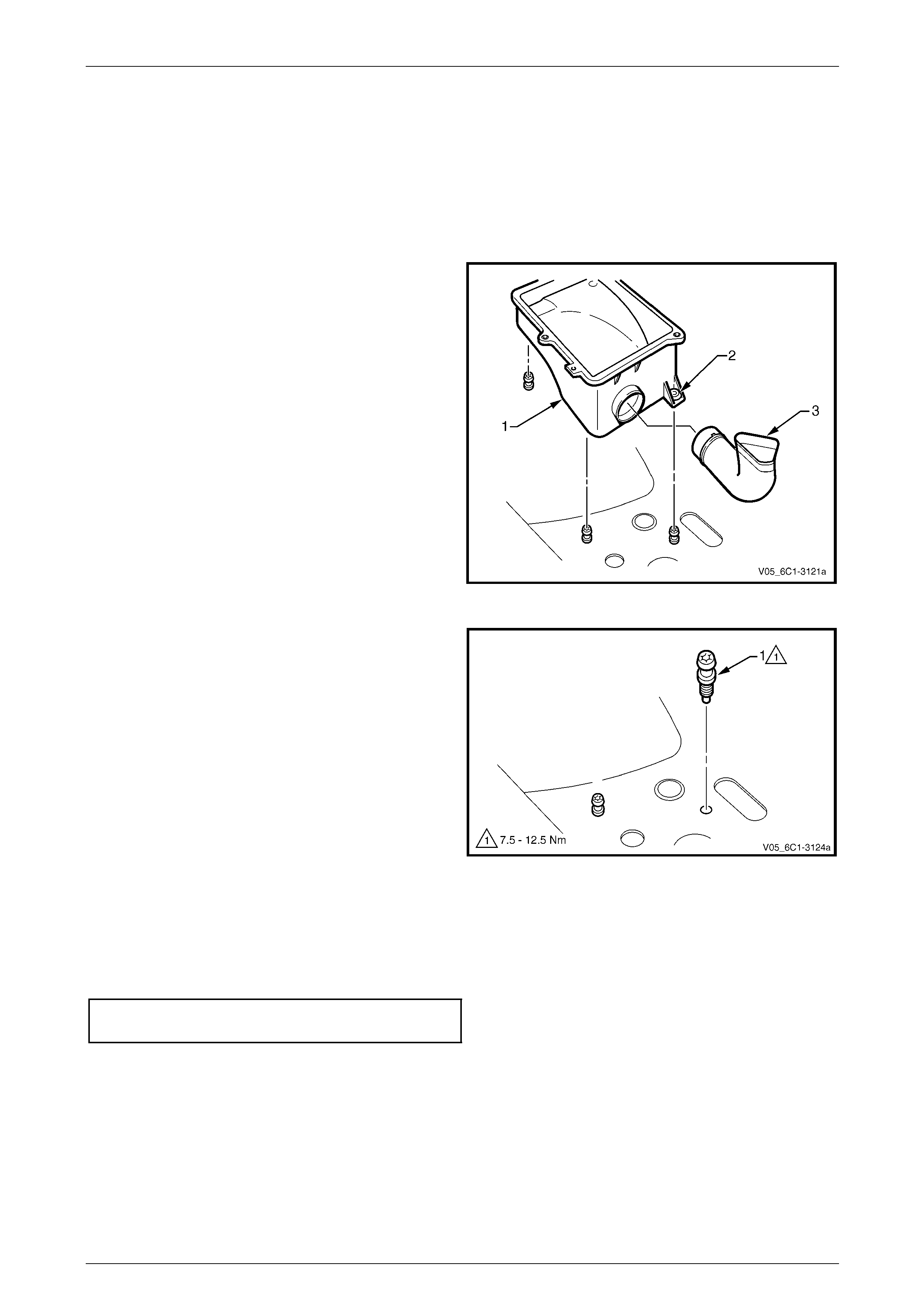

4 Remove the screw (1), three places, attaching the air

cleaner upper housing (2) to the air cleaner lower

housing (3).

5 Remove the upper housing and air cleaner

element (4).

Figure 6C3-3 – 11

Reinstall

Reinstallation of the air cleaner upper housing is the reverse of the removal procedure, noting the follo wing:

Ensure the air cleaner element seal is

correctly located in the air cleaner lower

housing during installation. Failure to do this

may result in engine damage due to unfiltered

air entering the engin e air intake s ystem.

1 Reinstall the air cleaner element.

2 Reinstall the screws and tighten to the correct torque specification.

Air cleaner upper housing attaching

screw torque specification...........................2.0 – 3.0 Nm

3 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–19

Page 6C3-3–19

Air Cleaner Lower Housing Assembly

Remove

1 Turn the ignition switch off.

2 Remove the air cleaner up per housing and element as described previously.

3 Unclip the mass airflow sensor and air-conditioner pressure sensor wiring harness.

4 Grasp the air cleaner lower housing assemb ly (1), and

pull upward to release the i nsulator (2), three places,

from the retaining studs and remove the lower

housing.

5 If required, disengage the air cleaner air inlet duct (3)

from the lower housing.

Figure 6C3-3 – 12

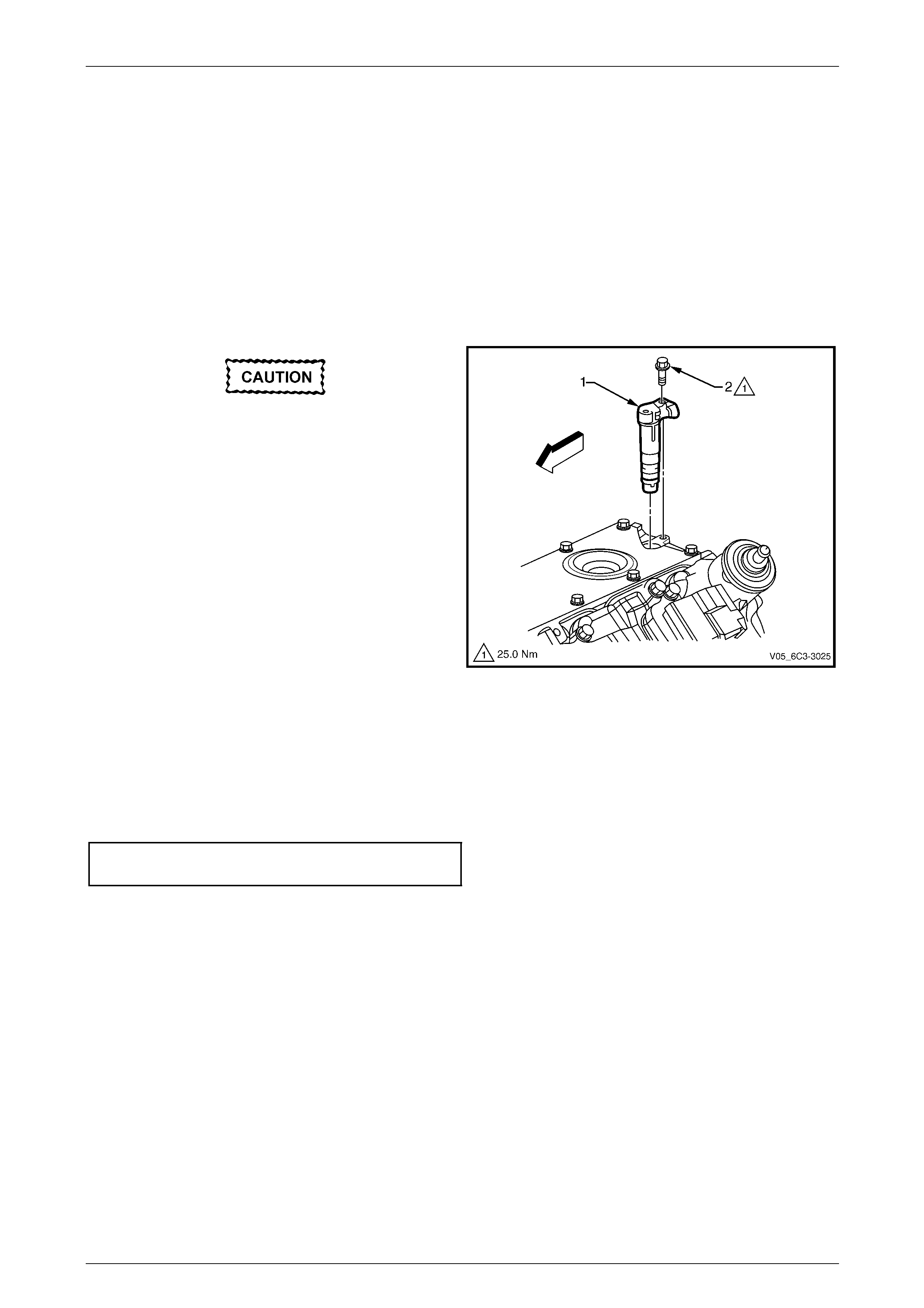

6 If required, remove the stud (1), three places, from the

fender inner panel.

Figure 6C3-3 – 13

Reinstall

Reinstallation of the air cleaner lower housing assembly is the reverse of the removal procedure, noting the following:

1 If previously removed, reinstall the studs and tighten to the correct torque specification.

Air cleaner lower housing assembly

retaining stud torque specification.............7.5 – 12.5 Nm

2 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–20

Page 6C3-3–20

3.5 Camshaft Position Sensor

LT Section No. — 02–000

Remove

1 Turn the ignition switch off.

2 Remove both engine dress covers, refer to Section 6A3 Engine Mechanical – GEN III V8.

3 Depressurise the fuel system, refer to Section 8A1 Fuel System.

4 Remove the intake manifold, refer to Section 6A3 Engine Mechanical – GEN III V8.

To avoid debris from entering the engine,

clean the area around the engine camshaft

position (CMP) sensor before removal and

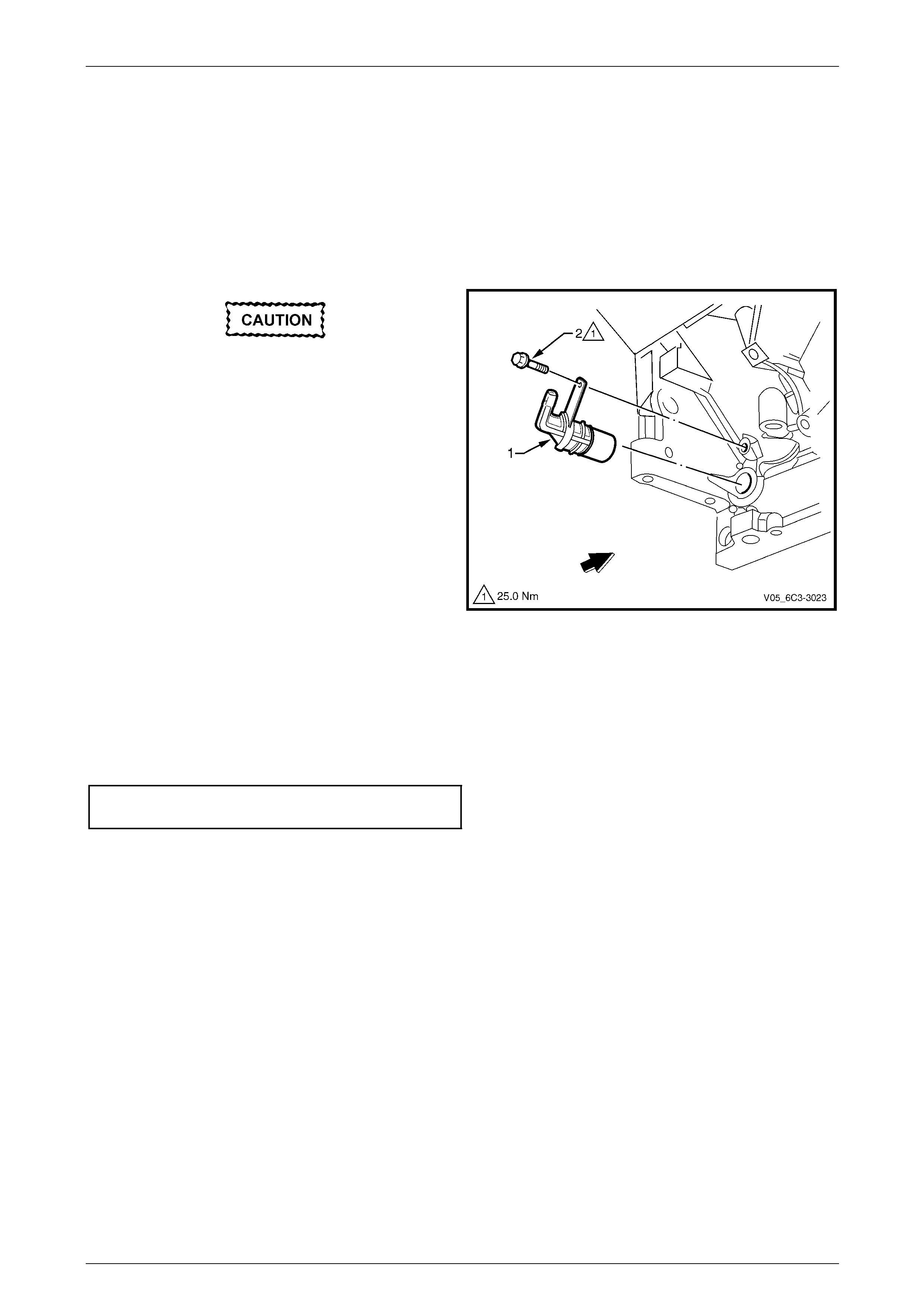

plug or cover the opening once removed.

5 Disconnect the wiring connector from the CMP sensor

(1).

6 Remove the CMP sensor retaining bolt (2).

7 Remove the CMP sensor, by first twisting the sensor

to break the O-ring seal, then pull upward with a

twisting back and forth motion.

Figure 6C3-3 – 14

Reinstall

Reinstallation of the camshaft position (CMP) sensor is the reverse of the removal procedure, noting the following:

1 Lubricate the CMP sensor O-ring with clean engine oil prior to installation.

2 Reinstall the bolt and tighten to the correct torqu e specification.

Camshaft position (CMP) sensor

retaining bolt torque specification.......................25.0 Nm

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–21

Page 6C3-3–21

3.6 Crankshaft Position Sensor

LT Section No. — 02–000

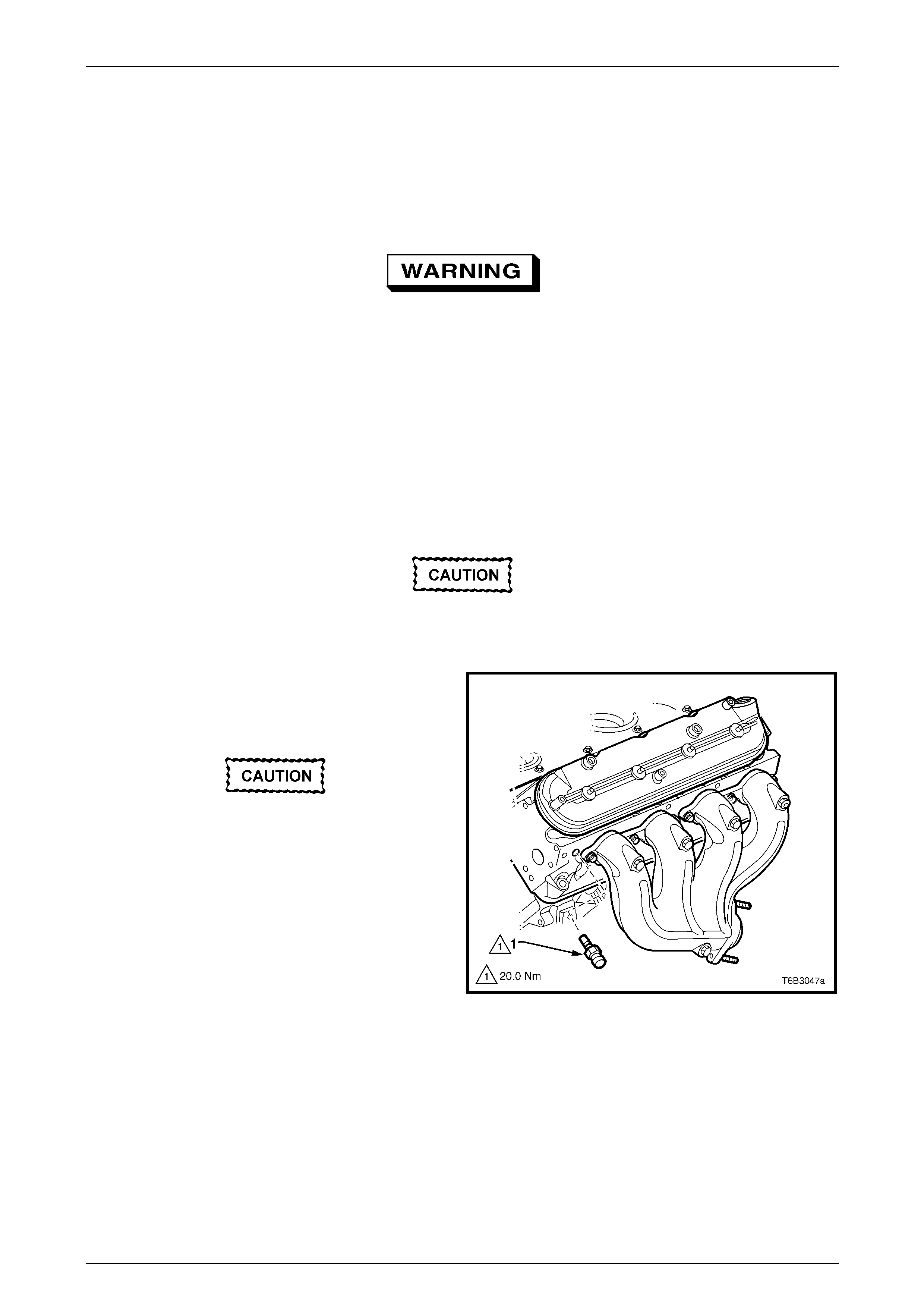

Remove

1 Turn the ignition switch off.

2 Remove the starter motor, refer to Section 6D3-2 Starting System – GEN III V8.

Clean the area around the crankshaft

position (CKP) sensor before removal to

avoid debris from entering the engine.

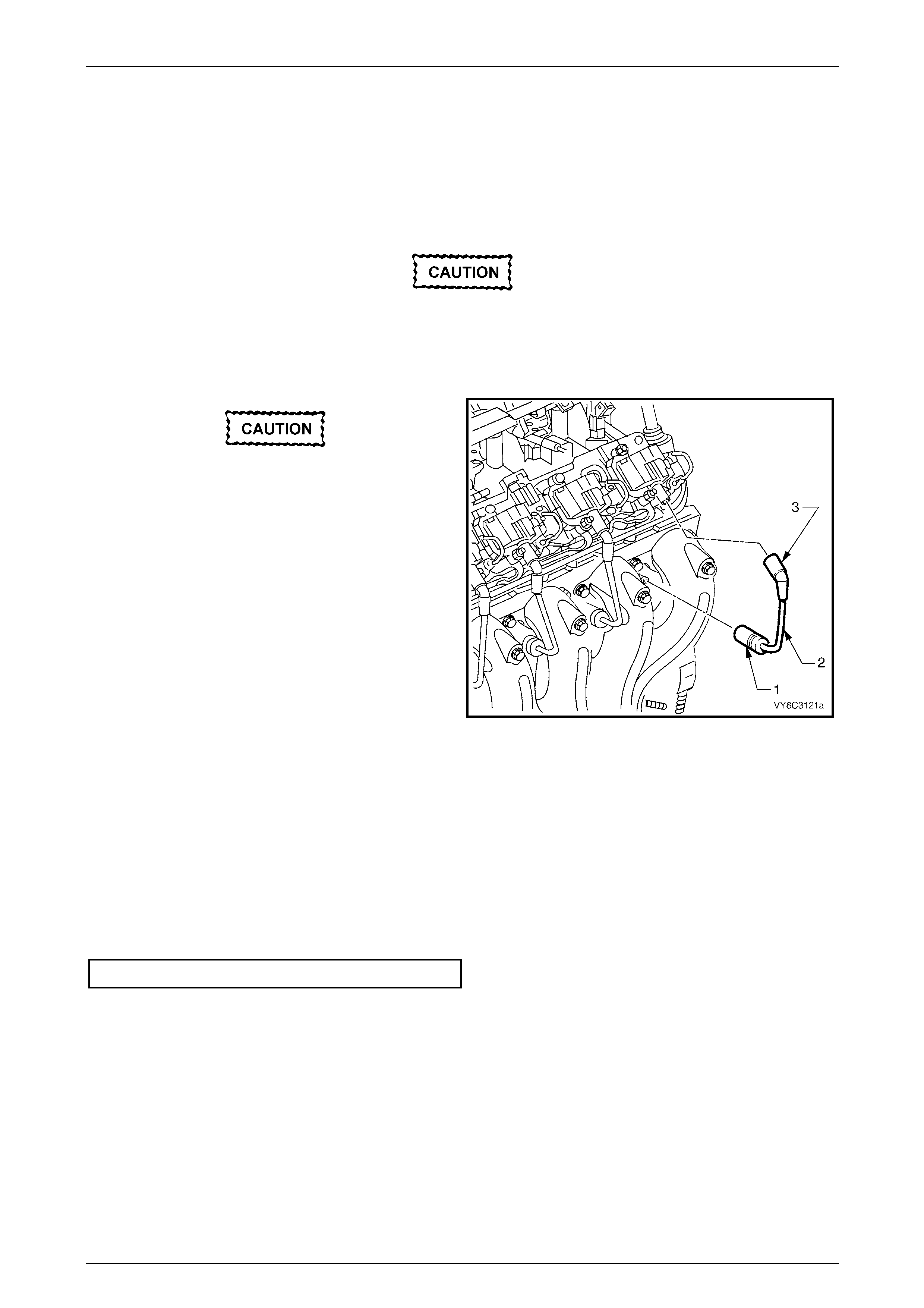

3 Disconnect the wiring connector from the CKP sensor

(1).

4 Remove the bolt (2) and remove the sensor.

Figure 6C3-3 – 15

Reinstall

Reinstallation of the crankshaft position (CKP) sensor is the reverse of the removal procedure, noting the following:

1 Lubricate the CKP sensor O-ring with clean engine oil prior to installatio n.

2 Reinstall the bolt and tighten to the correct torqu e specification.

Crankshaft position (CKP) sensor

retaining bolt torque specification.......................25.0 Nm

3 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–22

Page 6C3-3–22

3.7 Engine Coolant Temperature Sensor

LT Section No. — 02–000

Remove

To avoid serious personal injury, never

remove the engine coolant temperature ECT

sensor when the engine is hot. Allow the

engine to cool to ambient temperature (less

than 50° C) before performing this procedure.

1 Raise the vehicle and suppor t on safety stands, refer to Section 0A General Information for the location of jacking

and support points.

2 Drain the engine coolant, refer to Section 6B3 Engine Cooling – GEN III V8.

3 Lower the vehicle.

4 Remove the left-hand engine dress cover, refer to Section 6A3 Engine Mechanical – GEN III V8.

Clean the area around the engine coolant

temperature (ECT) sensor before removal to

avoid debris from entering the engine.

5 Disconnect the wiring connector from the ECT sensor

(1).

6 Remove the No. 1 spark plug lead from the spark plug.

Use care when handling the ECT sensor as

damage will affect the operation of the fuel

control system.

7 Remove the ECT sensor.

Figure 6C3-3 – 16

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–23

Page 6C3-3–23

Test

To prevent component damage, use

connector test adaptor kit J 35616-A.

Resistance Check

1 Suspend the ECT sensor and a suitable thermometer in a container of 50/50 DEX-COOL® long life co olant or

equivalent and water.

NOTE

Neither the ECT sensor or thermometer should

rest on the bottom of the container due to an

uneven concentration of heat at this point when

the container is heated.

2 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the ECT sensor and measur e

the resistance across terminals 1 and 2.

3 Whilst heating the container, observe the resistance

values as the temperature increases and compare the

temperature/resistance chang e to the specifications.

Figure 6C3-3 – 17

4 If the resistance is not within specifications, replace

the ECT sensor.

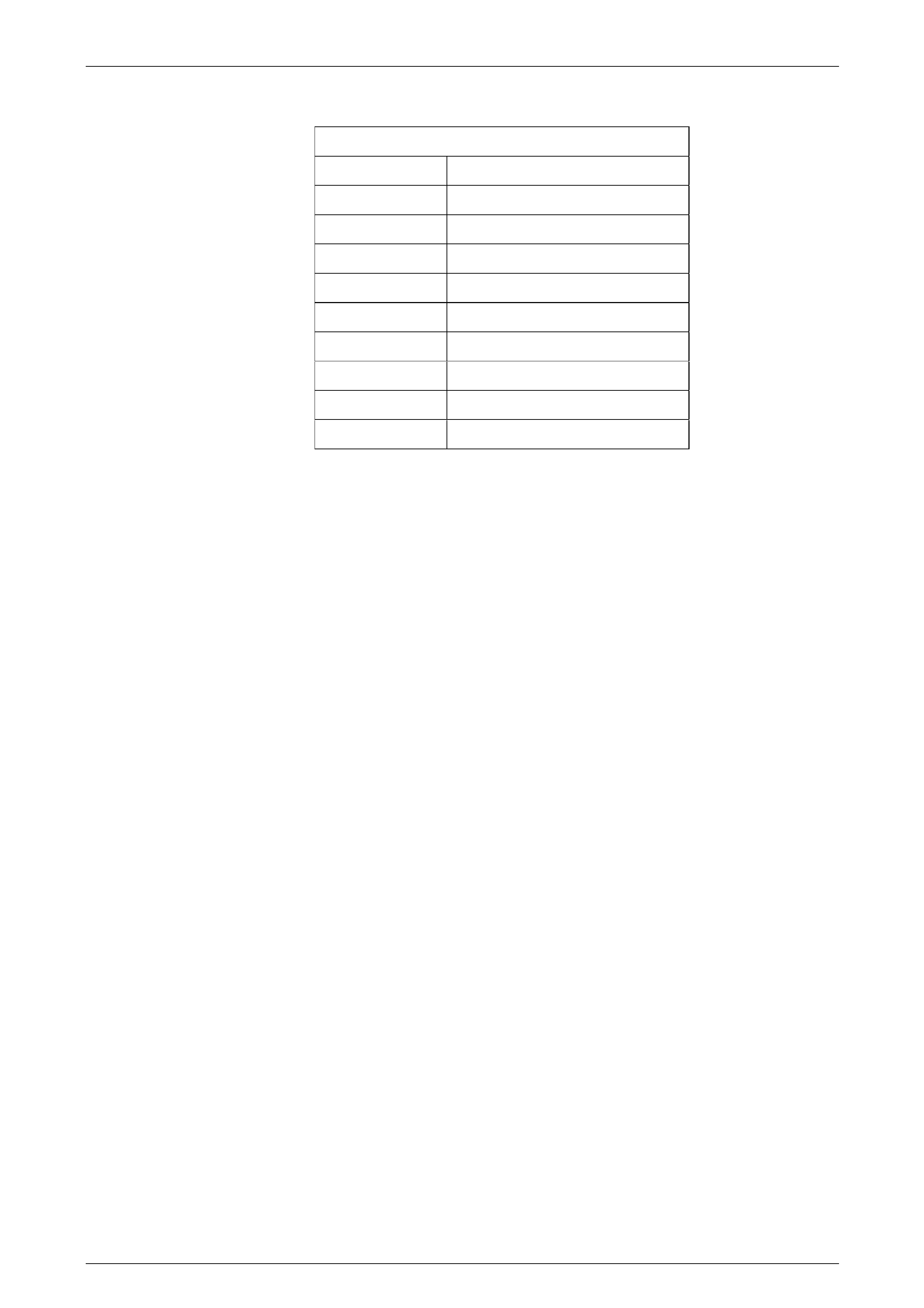

Engine Coolant Temperature Vs Resistance

Temperature °C Resistance – Ohms (Ω)

-10 16,180

0 9,420

20 3,520

25 2,796

40 1,459

60 667

80 332

100 177

120 100

140 60

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–24

Page 6C3-3–24

Reinstall

Reinstallation of the engine coolant temperature (ECT) sensor is the reverse of the removal proc edure, noting the

following:

1 Coat the ECT sensor thread with Loctite 242 or equivalent.

2 Tighten the ECT sensor to the correct torque specification.

Engine coolant temperature (ECT)

sensor torque specification ................................20.0 Nm

3 Refill the cooling system, refer to Section 6B3 Engine Cooling – GEN III V8.

4 Road test the vehicle and check for correct operation, taking particular note there is no coolant leakage.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–25

Page 6C3-3–25

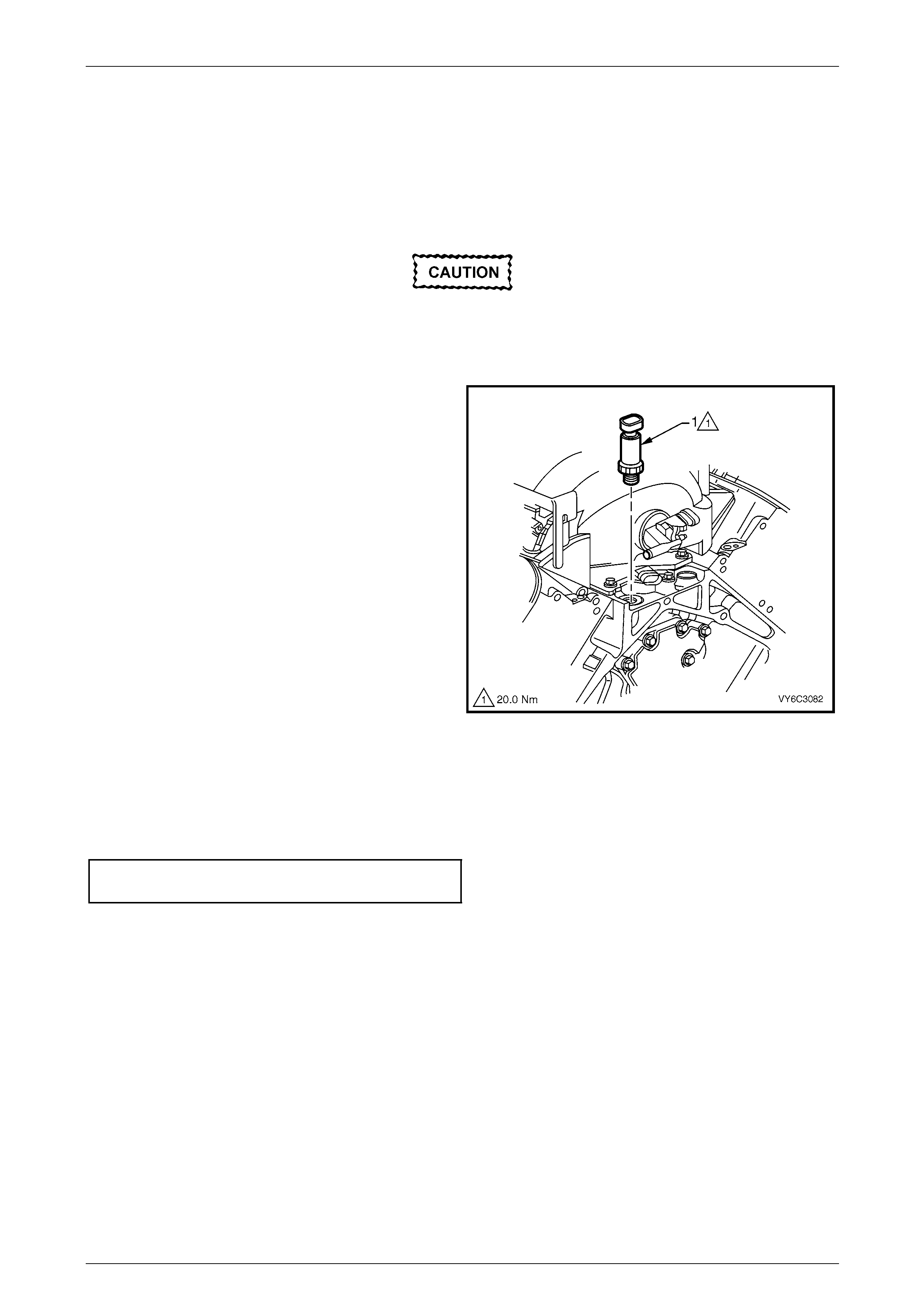

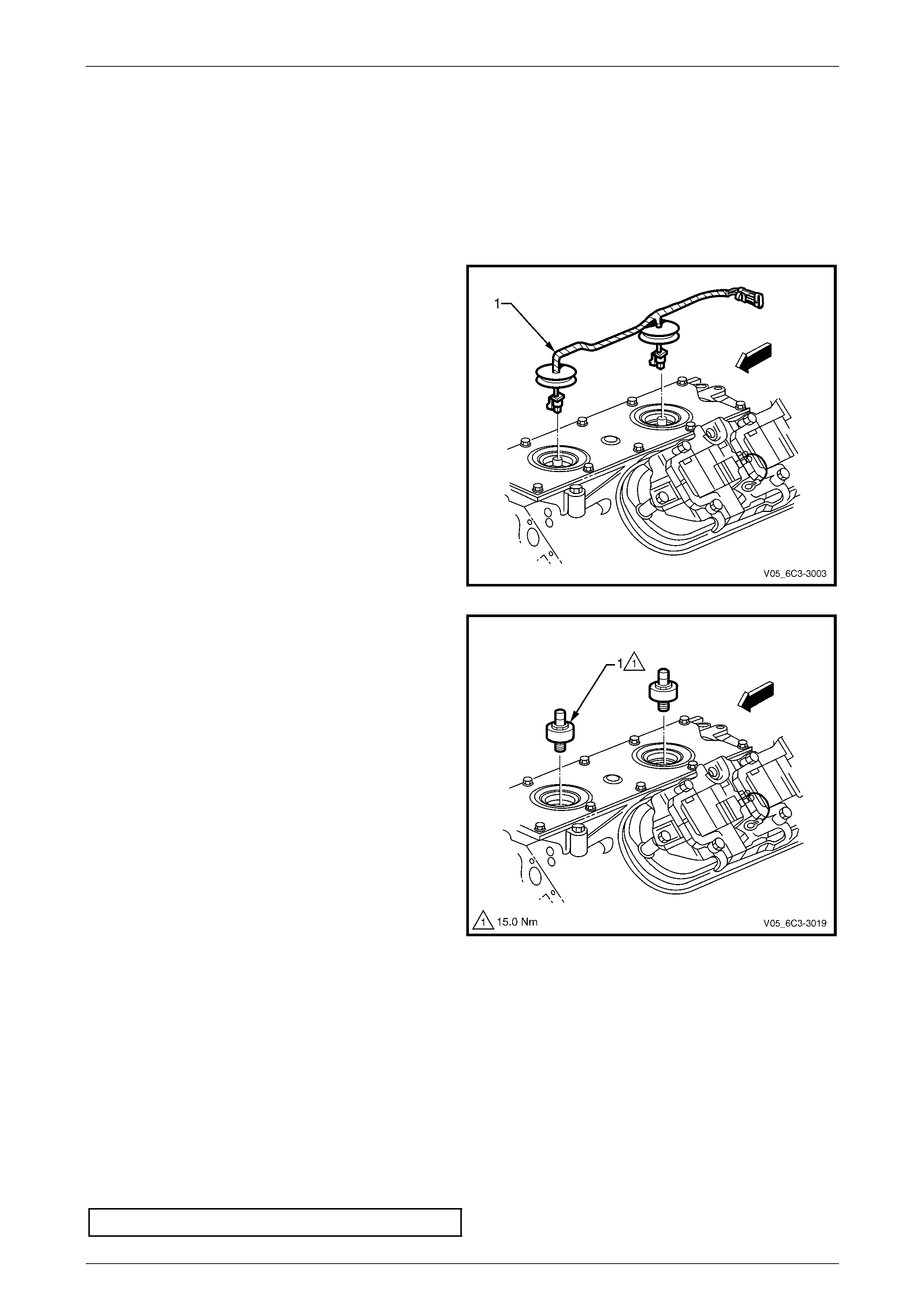

3.8 Engine Oil Pressure Sensor

LT Section No. — 02–000

Remove

To avoid debris from entering the engine,

clean the area around the engine oil pressure

(EOP) sensor before removal and plug or

cover the opening once removed.

1 Disconnect the wiring connector from the engine oil

pressure (EOP) sensor (1).

2 Using tool J 41712, remove the EOP sensor.

Figure 6C3-3 – 18

Reinstall

Reinstallation of the engine oil pressure (EOP) sensor is the reverse of the removal procedure, noting the following:

1 Reinstall the EOP sensor and tighten to the correct torque specification.

Engine oil pressure (EOP) sensor

torque specification............................................20.0 Nm

2 Check the engine oil level and top up if necessary.

3 Start the engine and inspect for oil leaks.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–26

Page 6C3-3–26

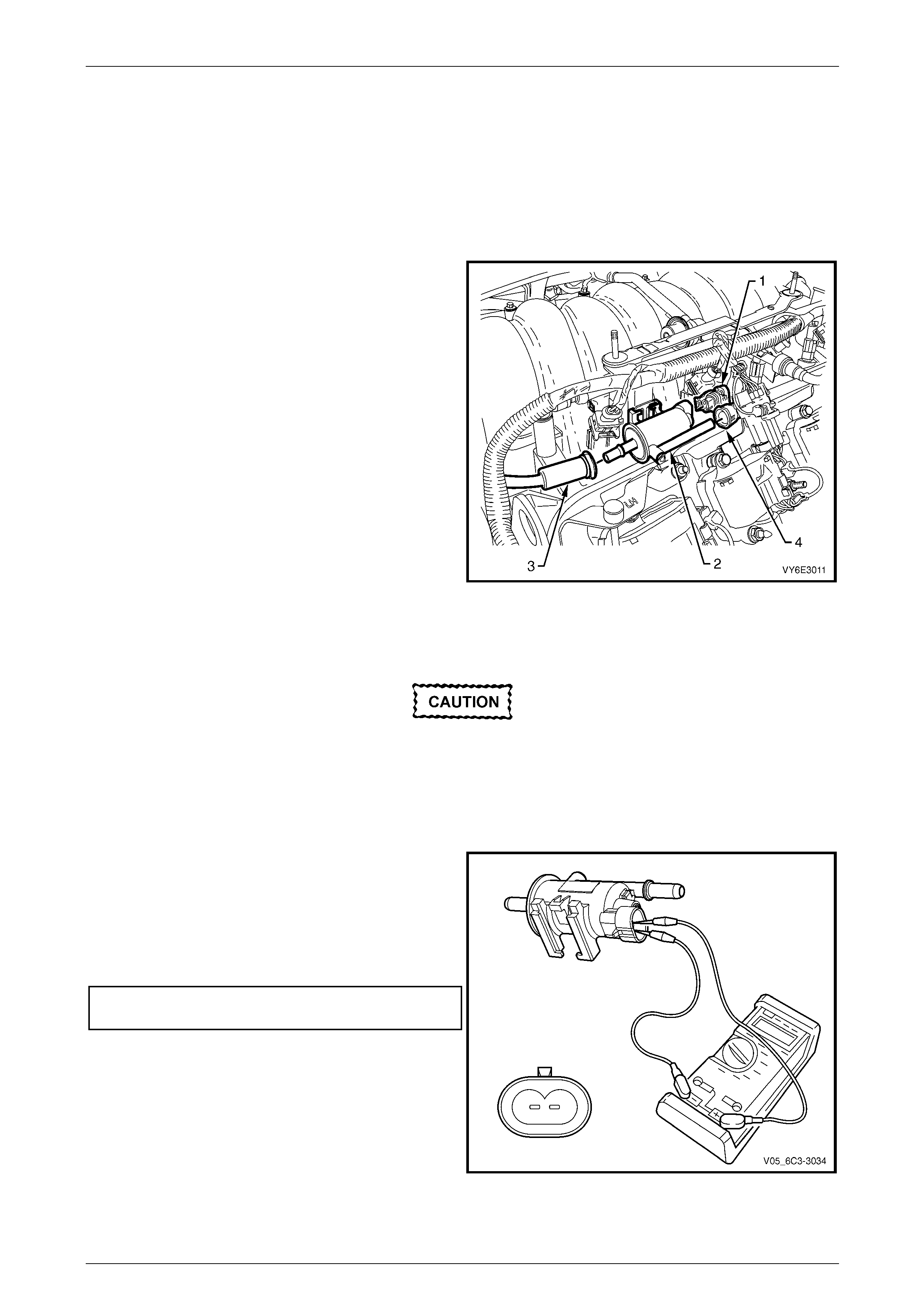

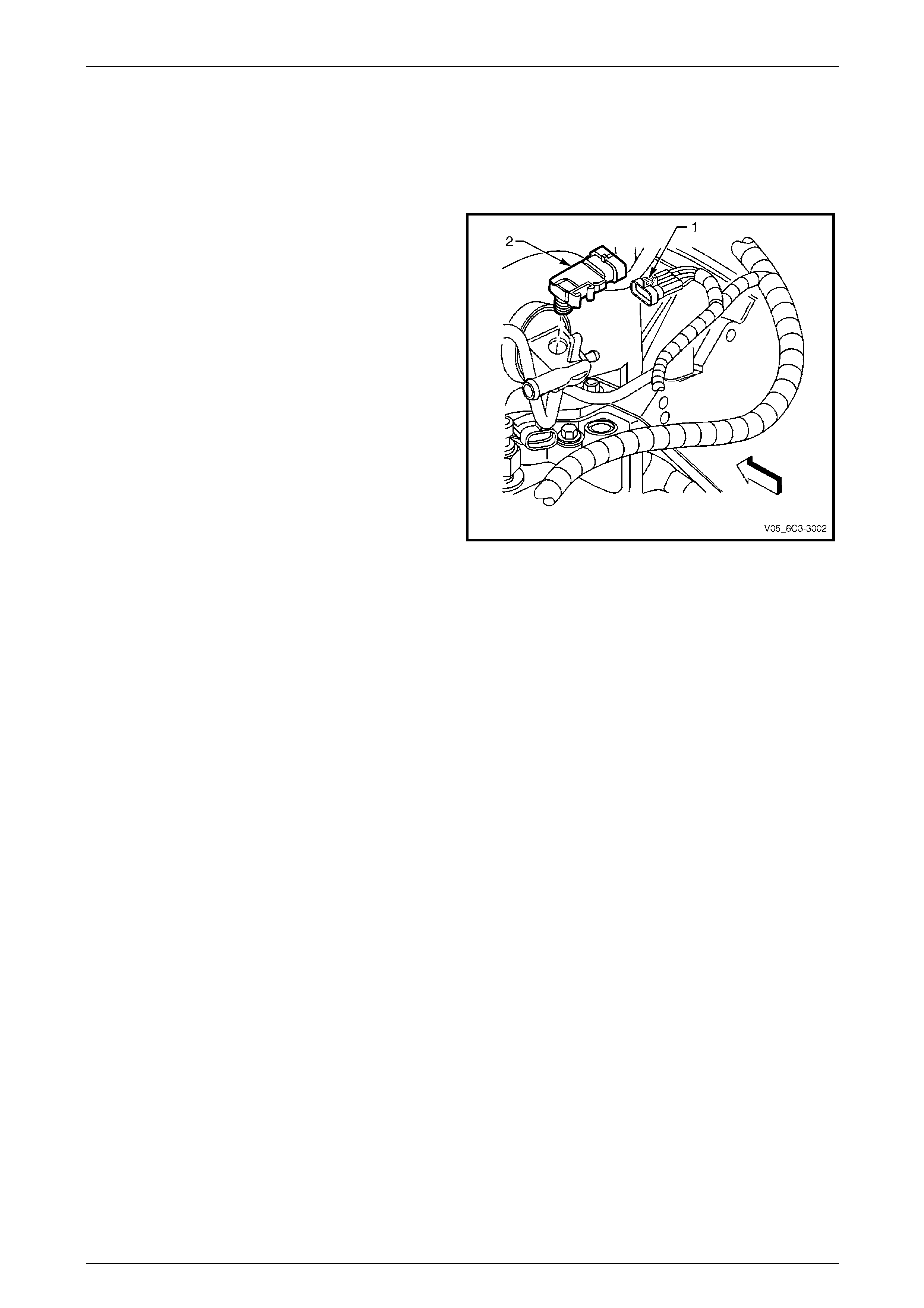

3.9 EVAP Canister Purge Solenoid Valve

LT Section No. — 03–165

Remove

1 Remove the left-hand engine dress cover, refer to Section 6A3 Engine Mechanical – GEN III V8.

2 Disconnect the wiring connector (1) from the EVAP

canister purge solenoid valve (2).

3 Disconnect the front hose (3) by squeezing the

retaining clip and pulling the hose from the solenoid

valve.

4 Disconnect the rear hose quick connect (4) from the

solenoid valve, refer to Section 8A1 Fuel System.

5 Lift and remove the solenoid valve from the mounting

bracket.

Figure 6C3-3 – 19

Test

To prevent component damage:

• Use connector test adaptor kit J 35616-A.

• When applying 12 Volts to a component,

always use a 3 Amp fused wire.

Resistance Check

1 Using a digital ohmmeter and connector test adaptor

kit J 35616-A, measure the resistance acr oss the

wiring connector terminals.

2 Compare the reading against the specification.

3 If the resistance is not within specification, replace the

EVAP canister purge valve.

EVAP canister purge valve

resistance @ 20° C....................................18.0 – 22.0 Ω

Figure 6C3-3 – 20

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–27

Page 6C3-3–27

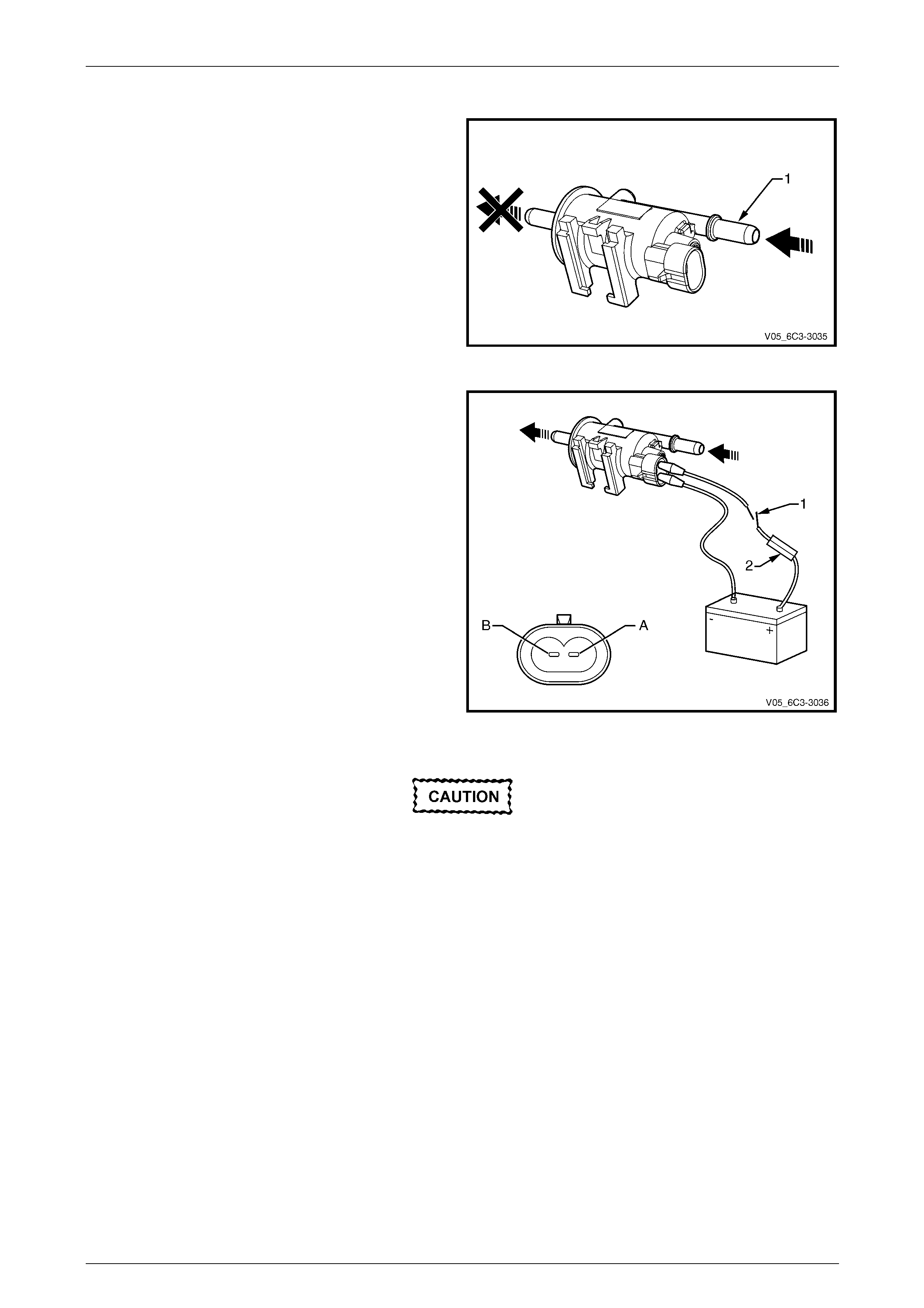

Functional Test

1 Attempt to blow air through the EVAP canister purge

valve inlet port (1). If air passes through the valve, the

valve is faulty and should be replaced.

Figure 6C3-3 – 21

2 Using connector test adaptor kit J 35616-A, connect a

12 Volt battery, an on/off switch (1) and a 3 Amp fused

wire (2) to the EVAP canister purge valve terminals as

follows:

• Positive lead to terminal (A).

• Negative lead to terminal (B).

Figure 6C3-3 – 22

Do not apply 12 Volts to the EVAP canister

purge valve continuously for more than three

seconds as the EVAP canister purge valve

will be damaged.

3 Turn the switch on, and listen for an audi ble click as the EVAP canister purge valve operates. Whilst the switch is in

the on position, blow air through the inlet port.

4 If no air passes through the EVAP canister purge valve, check the valve inlet and outlet ports for any obstructions

and rectify if necessary. If there are no o bstru ctions, replace the valve.

Reinstall

Reinstallation of the EVAP canister pur ge solenoid valve is the reverse of the removal procedure.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–28

Page 6C3-3–28

3.10 Fuel Pulse Dampener

LT Section No. — 03–375

Remove

A depressurised fuel system contains

residual fuel that can be spilled durin g ser vice

operations. Refer to Section 00 Warnings,

Cautions and Notes for further information

on handling fuel.

1 Depressurise the fuel system, refer to Section 8A1 Fuel System.

2 Turn the ignition switch off.

3 Remove left-hand engine dress cover, refer to Section 6A3 Engine Mechanical – GEN III V8.

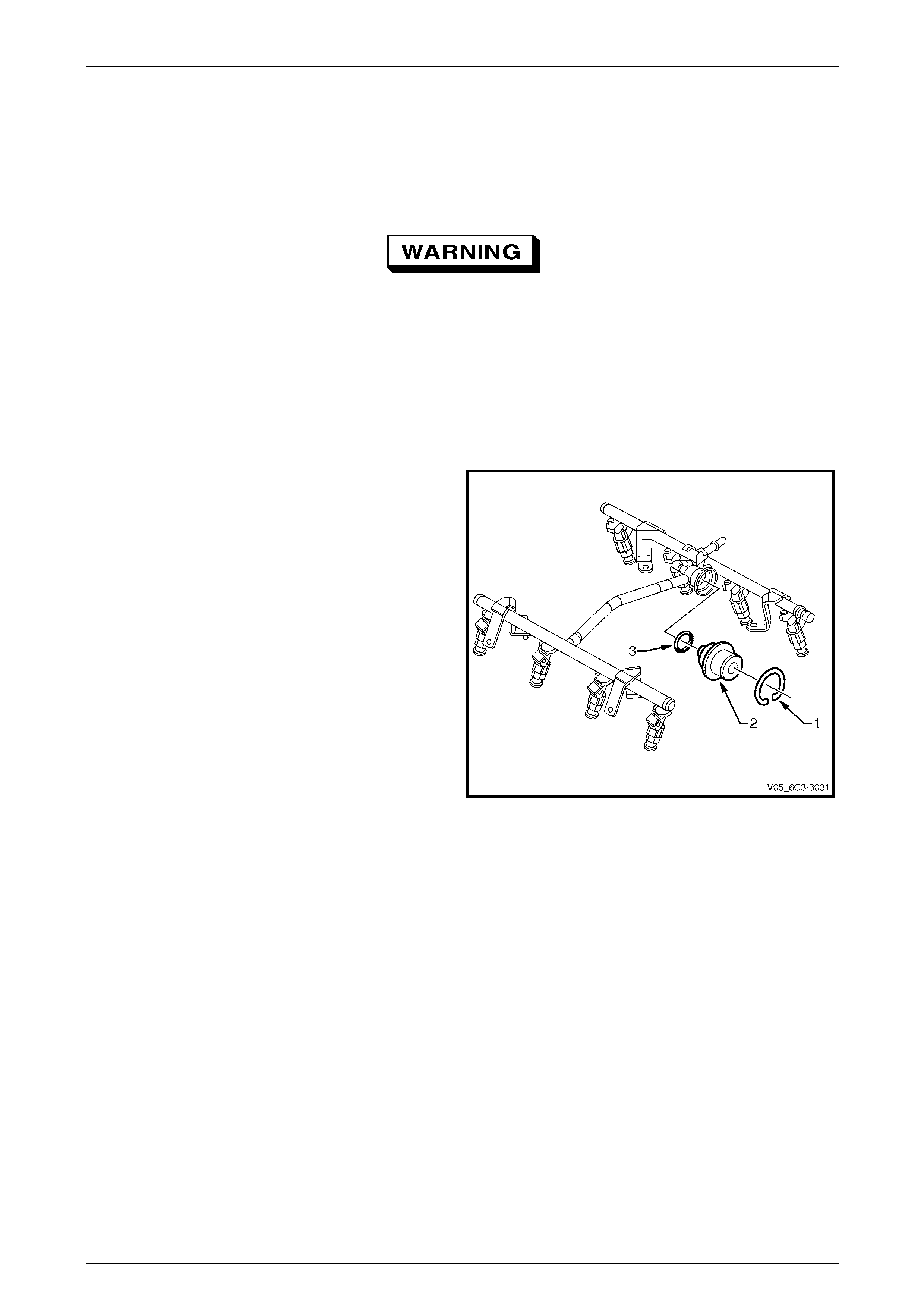

4 Clean any dirt from the fuel rail around the fu el pulse

dampener.

5 Remove the circlip (1) and dis c ard.

6 Remove the fuel pulse dampener (2) from the fuel rail.

7 Remove and discard the O-ring (3) from the fuel pulse

dampener.

Figure 6C3-3 – 23

Reinstall

Reinstallation of the fuel pulse dampener is the reverse of the removal procedure, noting the following:

1 Install a new O-ring on the fuel pulse damp en er and lubricate with clean engin e oil.

2 Install a new fuel pulse dampener circlip.

3 Perform the following procedure to inspect for leaks:

a Turn the ignition switch on for 2 seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Inspect for fuel leaks at the fuel pulse dampener.

4 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–29

Page 6C3-3–29

3.11 Fuel Rail Assembly

LT Section No. — 03–375

A depressurised fuel system contains

residual fuel that can be spilled durin g ser vice

operations, refer to Section 00 Warnings,

Cautions and Notes for further information

on handling fuel.

Remove

1 Remove both engine dress covers, refer to Section 6A3 Engine Mechanical – GEN III V8.

2 Depressurise the fuel system, refer to Section 8A1 Fuel System.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes

before disconnecting the battery.

3 Disconnect the negative battery cable.

4 If fitted, remove the front suspension strut brace, refer to Section 1A1 Body.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part, refer to Section 00 Warnings,

Cautions and Notes for correct workshop

practices when using co mpressed air.

5 If required, use compressed air to remove an y foreign material from around the area where the fuel injectors enter

the intake manifold.

6 Disconnect the fuel feed hose from the fuel rail, refer to Section 8A1 Fuel System.

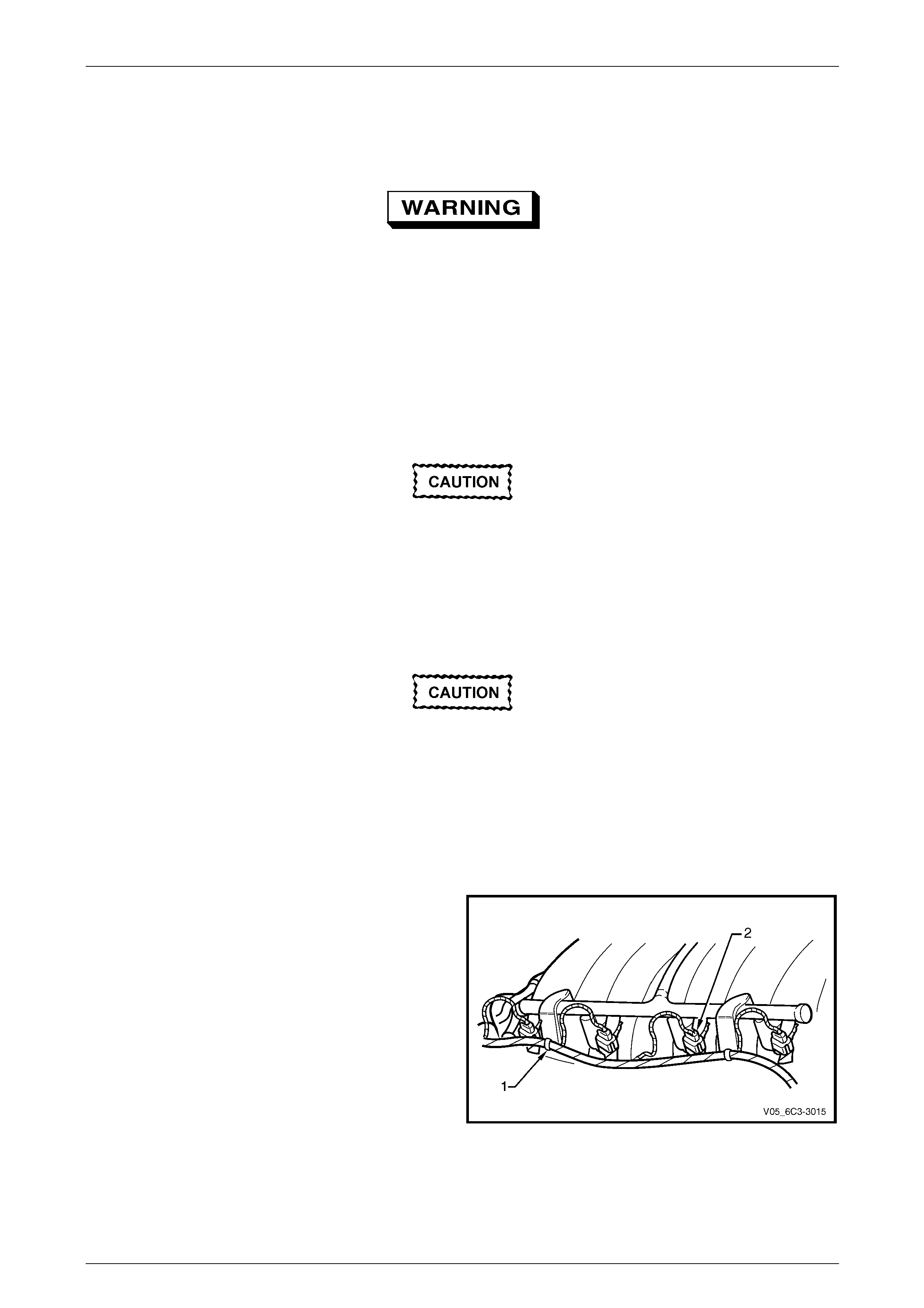

7 Detach the wiring harness clips (1), four places.

8 Disconnect the wiring connector (2), eight places, from

the fuel injectors. Identify the connectors with their

corresponding injectors to ensure correct sequential

injector firing order after reassembly.

Figure 6C3-3 – 24

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–30

Page 6C3-3–30

9 Remove the four double ende d studs (1) securing the

fuel rail (2) to the intake manifold.

Remove the fuel rail assembly carefully to

avoid damage to the injector spray tips.

Support the fuel rail after the fuel rail is

removed to avoid damaging the fuel rail

components.

10 Carefully lift the fuel rail assembl y (2) clear of the

intake manifold.

11 Cap the fittings and plug the h oles when servicing the

fuel system to prevent dirt and other contamina nts

from entering open pipes and passa ges.

12 Remove and discard the in jector lower O-ring seal

from the spray tip end of each injector. Figure 6C3-3 – 25

Disassemble

Fuel Injector Assembly

Remove

Take care when remo ving the fuel injectors to

prevent damage to the electrical connector

pins on the injector and to prevent damage to

the nozzle. Service the fuel injector as a

complete assembly only. The fuel injector is

an electrical component. Do not immerse the

fuel injector in any type of cleaner.

1 Remove the fuel pulse dampener, refer to 3.10 Fuel Pulse Dampener.

2 Pull the injector retainer clip (1) to release the injector

from the fuel rail (2).

3 Remove the fuel injector (3) and discard the injector

retainer clip.

4 Remove and discard the injector O-ring seals (upper

4 and lower 5) from each end of the injector.

5 Repeat for each of the remaining injectors as

required.

Figure 6C3-3 – 26

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–31

Page 6C3-3–31

Test

To prevent component damage use connector

test adaptor kit J 35616-A.

1 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the fuel injector.

2 Measure the resistance across terminals A and B.

3 Compare the reading against the specification.

Fuel injector resistance @ 20° C ..............11.4 – 12.6 Ω

4 If the resistance is not within specifications, replace

the fuel injector.

Figure 6C3-3 – 27

Reinstall

When ordering new fuel injectors, ensure to

order the correct injector for the application

being serviced. The fuel injector assembly is

stamped with a part number identification, a

manufacturing date, a week code, and a

production plant number.

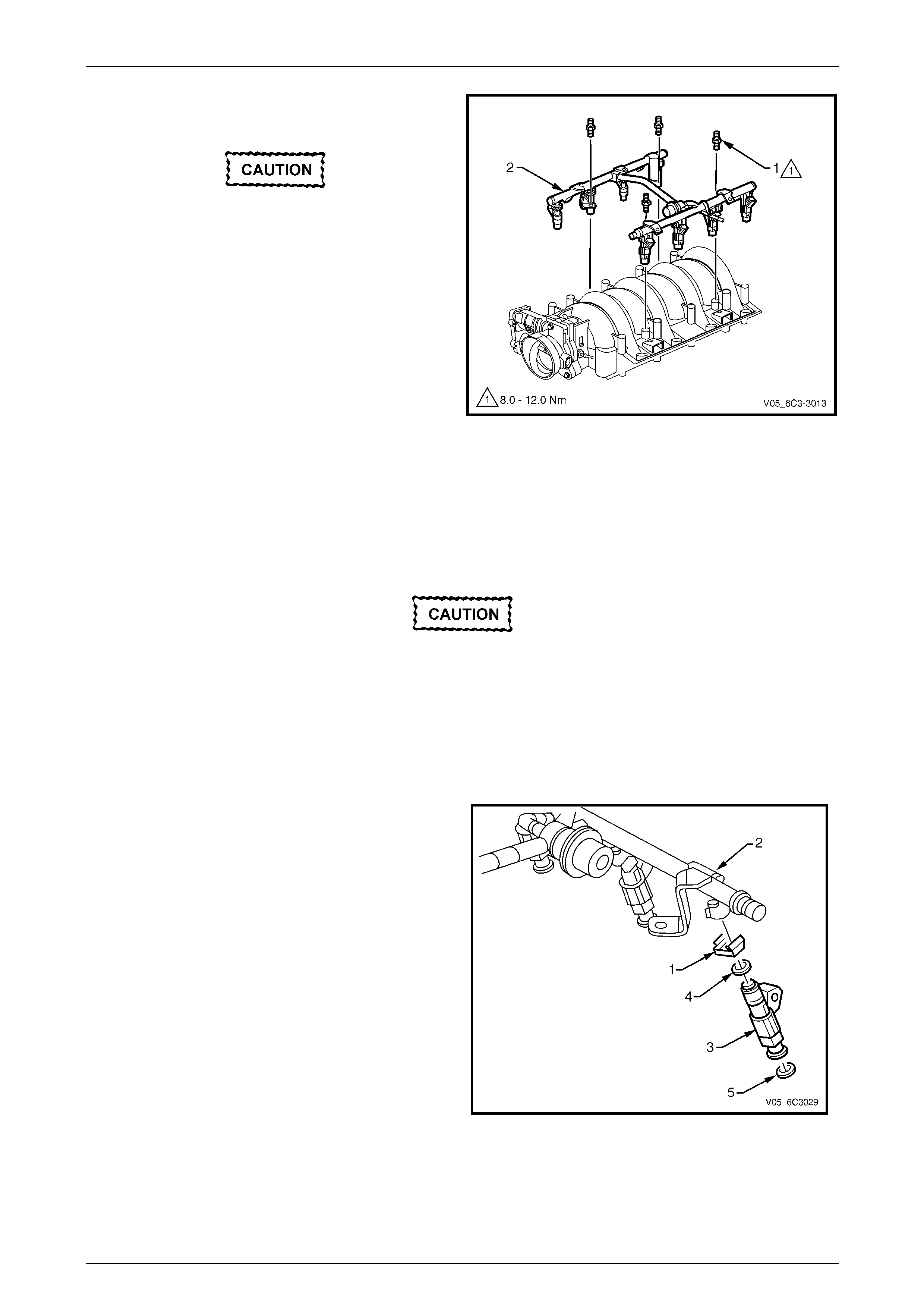

1 Lubricate a new upper injector O-ring seal (1) with

clean engine oil and install onto each injector.

2 Push the fuel injector into the fuel rail injector socket

with the electrical connector (2) facing outward.

3 Reinstall a new retainer clip to retain each injector.

The retainer clip locks on to a flange on the fuel rail

injector socket.

4 Reinstall the fuel pulse dampe ner,

refer to 3.10 Fuel Pulse Dampener.

Figure 6C3-3 – 28

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–32

Page 6C3-3–32

Reinstall

Reinstallation of the fuel rail assembly is the reverse of the removal procedure, noting the following:

1 Lubricate a new lower injector O-ring seal (1) with clean engine oil and install onto each injector.

2 Apply Loctite 242 or equiv ale nt to the cleaned threads of the fuel rail attachin g studs and tighten to the correct

torque specification.

Fuel rail attaching stud

torque specification...................................8.0 – 12.0 Nm

3 Connect the injector wiring connectors, ens uring the correct connector is installed to its corresponding injector to

ensure the correct sequential injector firing order.

NOTE

Rotate the injectors as required to avoid

stretching the wire harness.

4 Perform the following procedure to inspect for leaks:

a Turn the ignition switch on for 2 seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Inspect for fuel leaks at the fuel injectors and fuel feed hose.

5 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–33

Page 6C3-3–33

3.12 Heated Oxygen Sensor

LT Section No. — 00–450

To avoid the possibility of personal injury,

allow the exhaust pipe to cool to ambient

temperature (less than 50° C) before

attempting to remove the oxygen sensor.

NOTE

Some vehicles may be fitted with an additional

HO2S downstream of each catalytic converter.

These are fitted for production purposes but are

not used by the powertrain management s ystem.

Service Precautions

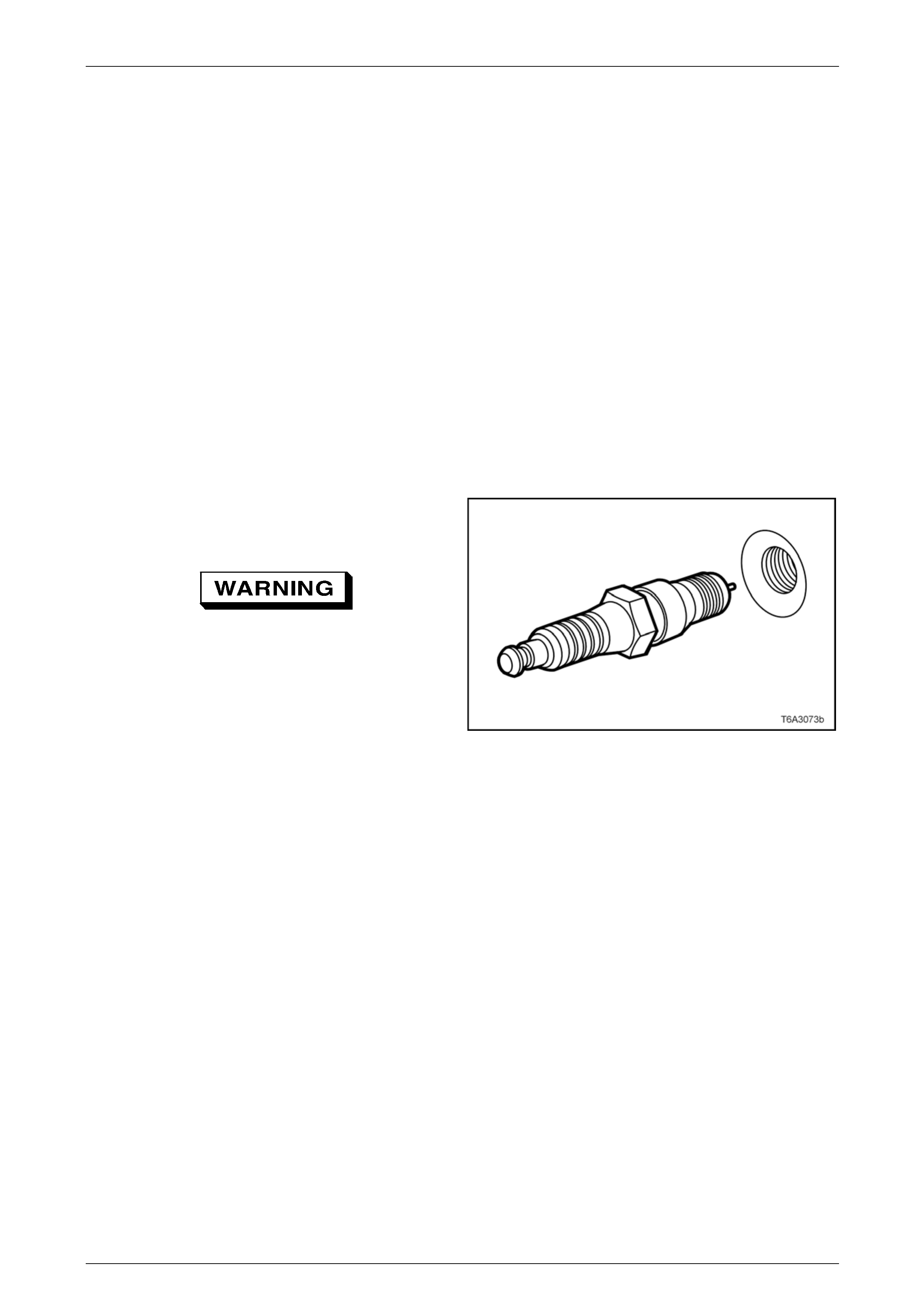

• Handle each heated oxygen sensor (HO2S) carefully. Do not drop it, and keep it free of grease, dirt and other

contaminants. Do not use cleaning solvents of any type on the sensor.

• Do not repair the sensor or any of its parts, including the wiring and connector. Replace the oxygen sensor if any

damage is evident.

• The oxygen sensor may be di fficult to remove when the engine is cold. Excessive force may damage the threads in

the exhaust manifold or exhaust pipe.

• It may be necessary to lower the exhaust system to gain sufficient access to a HO2S and/or its connector, refer to

Section 8B Exhaust System.

• If the HO2S has been removed, but not replaced, apply anti-seize compound to the threads prior to installation.

New oxygen sensors will already have the anti-seize compound applied.

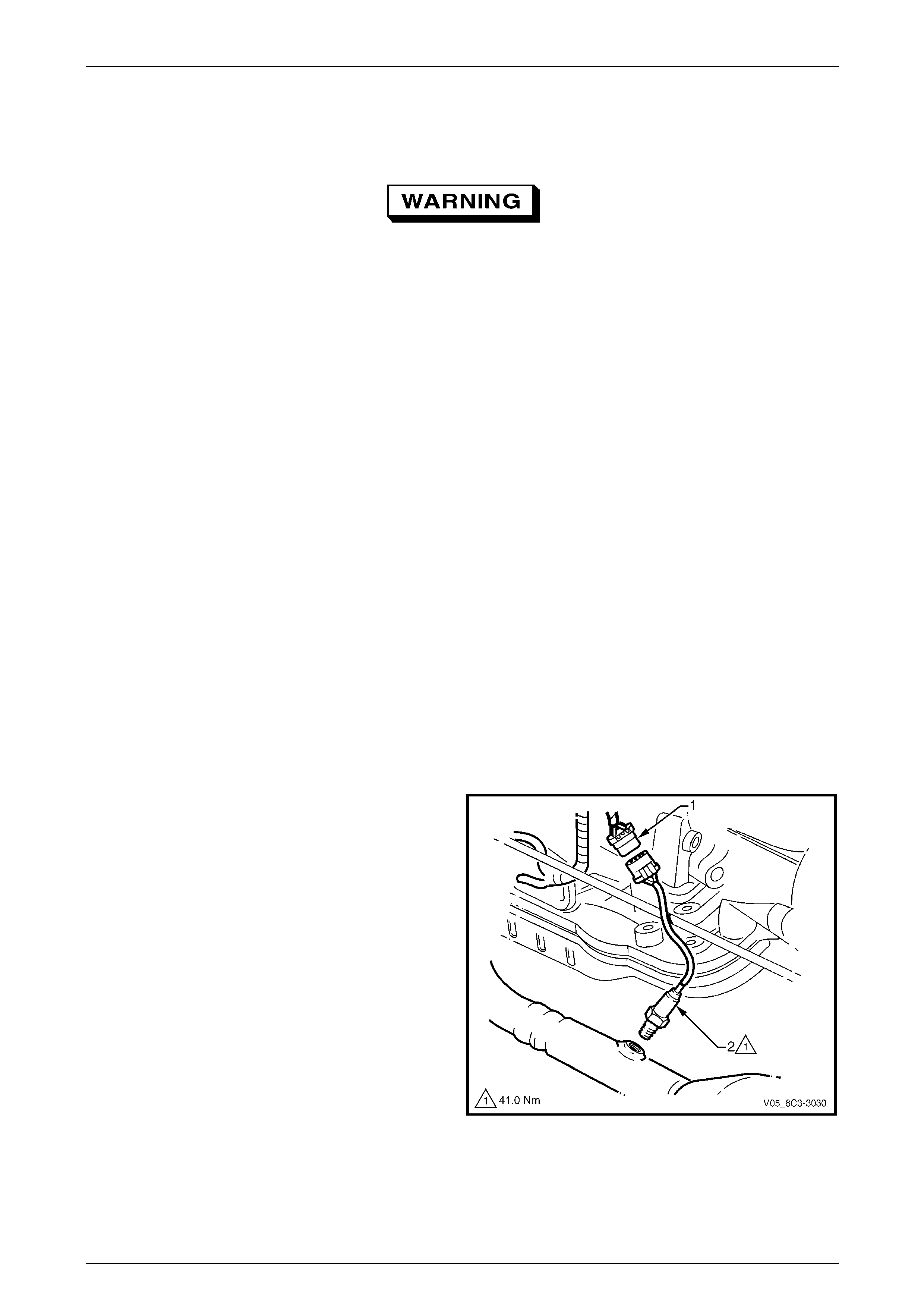

Remove

NOTE

While only the left-hand HO2S (bank 1) is sho wn,

the procedure for the right-hand sensor (bank 2)

is similar.

1 Raise the front of vehicle and support on safety stands, refer to Section 0A General Information for the location of

jacking and support points.

2 Disconnect the HO2S wiring harness connector (1).

3 Loosen and carefully remove the HO2S (2) from the

exhaust pipe.

Figure 6C3-3 – 29

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–34

Page 6C3-3–34

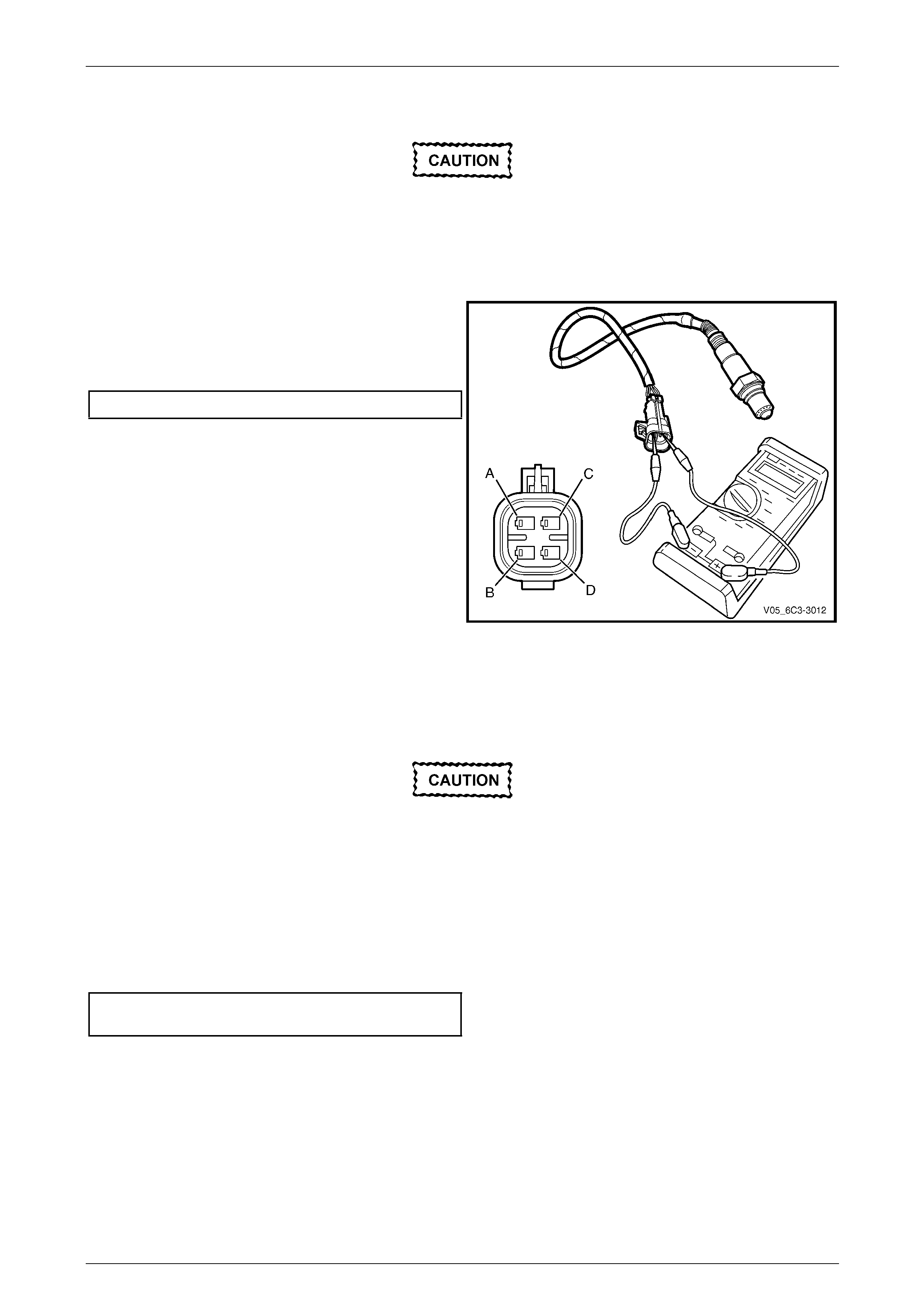

Test

• Under no circumstances should battery

voltage be applied to the HO2S heater.

• To prevent component damage use

connector test adaptor kit J 35616-A.

Heater Resistance Check

1 Using a digital ohmmeter and connector test adaptor

kit J 35616-A, measure the resistance acr oss

terminals C and D of the wiring harness connector.

2 Compare the reading against the specification.

HO2S heater resistance @ 20° C..................4.7 – 5.7 Ω

3 If the resistance is not within specification, replace the

HO2S.

Figure 6C3-3 – 30

Reinstall

Reinstallation of the heated o x ygen sensor (HO2S) is the reverse of the removal proced ure, notin g the following:

A special anti-seize compound is used on the

HO2S threads. New HO2S will already have

the anti-seize compound applied.

If an HO2S has been removed, but not

replaced, then anti-seize compound must be

applied to the threads prior to installation.

1 Coat the cleaned threads of the sensor with anti-seize compound.

2 Tighten the HO2S to the correct torque specificatio n.

Heated oxygen sensor (HO2S )

torque specification............................................41.0 Nm

3 Road test the vehicle and check for correct operation, taking particular note that no exhaust leakage is evident.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–35

Page 6C3-3–35

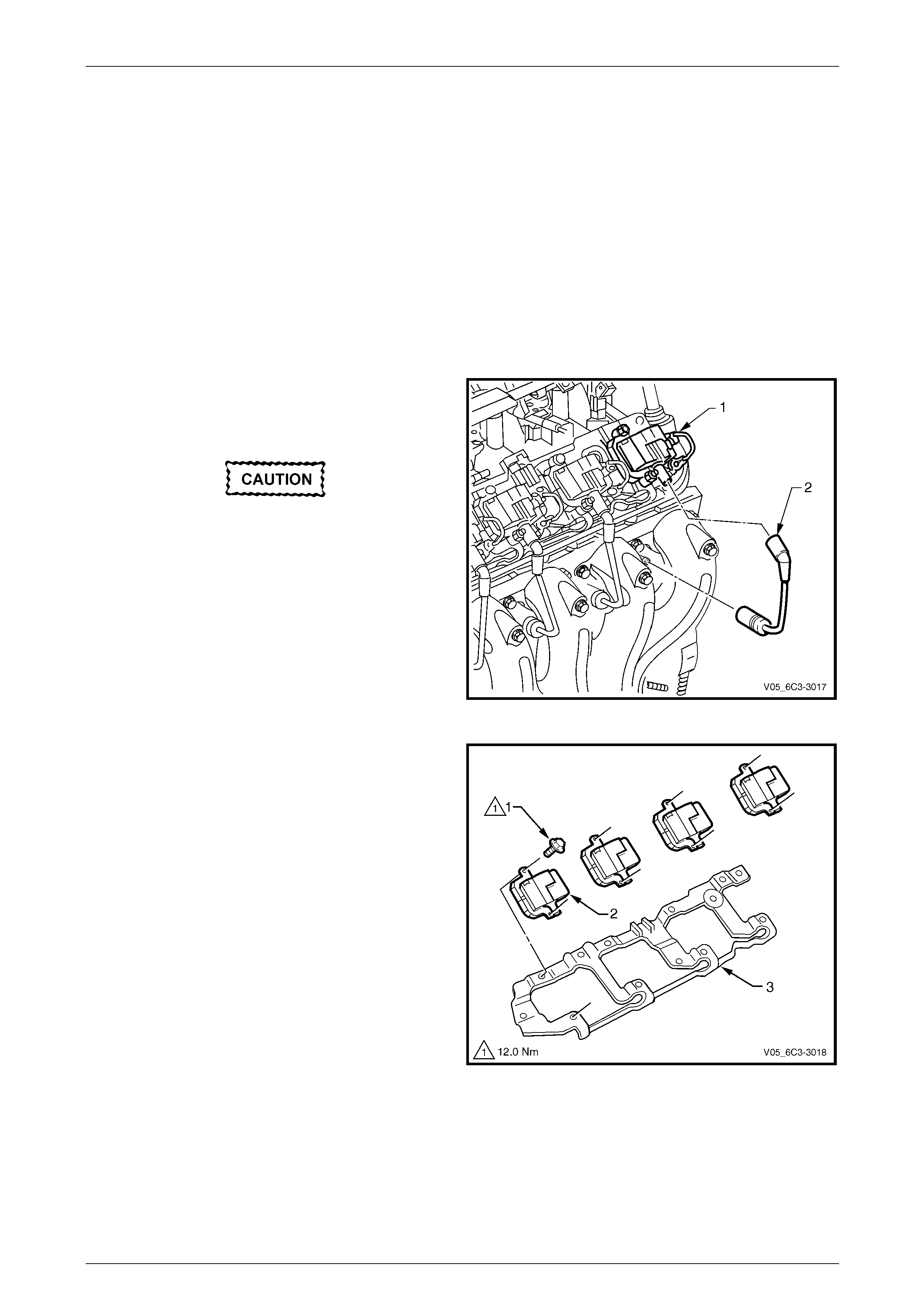

3.13 Ignition Coil Assembly

LT Section No. — 02–235

NOTE

The ignition module is incorporated into the

ignition coil assembly and is not serviced

separately.

Remove

1 Turn the ignition switch off.

2 Remove the appropriate engin e dress cover(s), refer to Section 6A3 Engine Mechanical – GEN III V8.

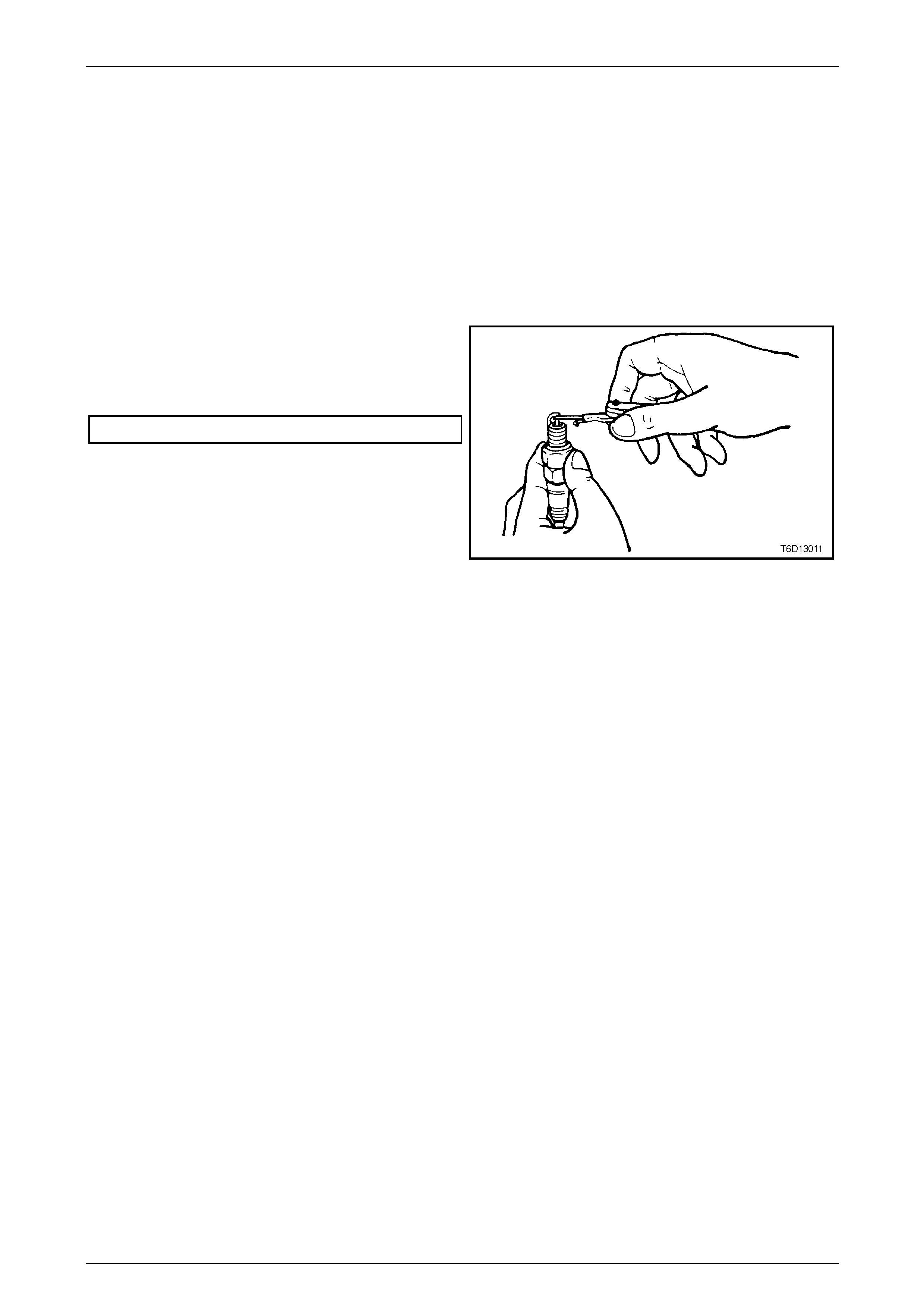

3 Remove the connector protection assurance (CPA)

lock (1) securing the wiring connector to the ignition

coil assembly and disconnect the wiring connector.

Never pull on the ignition lead. Grasp the

ignition coil boot and twist to break the seal

before pulling directly from each coil

assembly.

4 Disconnect the spark plug wire (2) at the coil

assembly.

Figure 6C3-3 – 31

5 Remove the attaching screw (1), two places.

6 Remove the ignition coil (2) from the mounti ng bracket

(3).

7 Repeat for the remaining ignition coil assemblies as

required.

Figure 6C3-3 – 32

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–36

Page 6C3-3–36

Test

Never probe the ignition coil with a 12 Volt

tester as the ignition coil will be damaged.

Due to the internal components of the ignition coil assembly, it is not possible to perform any primar y and/or secondary

resistance checks. For further information on the ignition coil operation,

refer to Section 6C3-1 Powertrain Management – GEN III V8 – General Info rmation.

Reinstall

Reinstallation of the ignition coil(s) is the reverse of the removal procedure, noting the following:

1 Reinstall the screws and tighten to the correct torque specification.

Ignition coil assembly attaching

screw torque specification..................................12.0 Nm

2 Road test the vehicle and check for correct operation.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–37

Page 6C3-3–37

3.14 Intake Air Temperature Sensor

The intake air temperature (IAT ) sensor is not serviced separately as it is part of the MAF sensor assembly,

refer to 3.17 Mass Air Flow Sensor and Intake Air Duct for the replacement procedure.

Test

To prevent component damage use connector

test adaptor kit J 35616-A.

Resistance Check

1 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the mass air flow (MAF)

sensor wiring connector terminals (A) and (B).

Do not use a high temperature heat gun as

damage to the MAF sensor will resu lt.

2 Whilst holding a thermometer (1), use a commercially

available hair dryer (2) to blow warm air through the

MAF sensor.

Figure 6C3-3 – 33

3 Observe the resistance values as the temperature

increases and compare t he temperature/resistance

change to the specifications.

4 If the resistance is not within specifications, replace

the MAF sensor.

Intake Air Temperature Vs Resistance

Temperature °C Resistance – Ohms (Ω)

-10 16177

0 9423

20 3515

30 2238

40 1459

60 667.5

80 332

100 176

120 99.8

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–38

Page 6C3-3–38

3.15 Knock Sensor

LT Section No. — 02–000

Remove

1 Depressurise the fuel system, refer to Section 8A1 Fuel System.

2 Turn the ignition switch off.

3 Remove both engine dress covers, refer to Section 6A3 Engine Mechanical – GEN III V8.

4 Remove the intake manifold,

refer to Section 6A3 Engine Mechanical – GEN III V8.

5 Remove the knock sensor patch wiring harness (1).

Figure 6C3-3 – 34

NOTE

Unless a deep socket is used, damage to the

sensor connector will result.

6 Remove the knock sensor (1), using a 22 mm deep

socket and suitable socket equipment.

7 Repeat for the remaining knock sensor as re quired.

Figure 6C3-3 – 35

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

NOTE

• Do not apply sealant to the thread of a new

sensor as it is coated with a sealant during

manufacture. Applying additional sealant may

affect the sensor's ability to detect engine

knock.

• Ensure the knock sensor is never over

tightened, as damage to the sensor can

occur.

1 Reinstall the knock sensor(s) and tighten to the correct torque spec ification.

Knock sensor torque specification .....................15.0 Nm

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–39

Page 6C3-3–39

3.16 Manifold Absolute Pressure Sensor

LT Section No. — 02–000

Remove

1 Disconnect the manifold absol ute pressure (MAP)

sensor wiring connector (1).

2 Twist the MAP sensor (2) forward to release it from the

intake manifold adaptor.

3 Pull the MAP sensor upward.

Figure 6C3-3 – 36

Reinstall

Reinstallation of the manifold absolute pressure (MAP) sensor is the reverse of the removal procedure, noting the

following:

1 Lightly coat the MAP sensor seal with clean engine oil.

2 Run the engine and check for vacuum leaks.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–40

Page 6C3-3–40

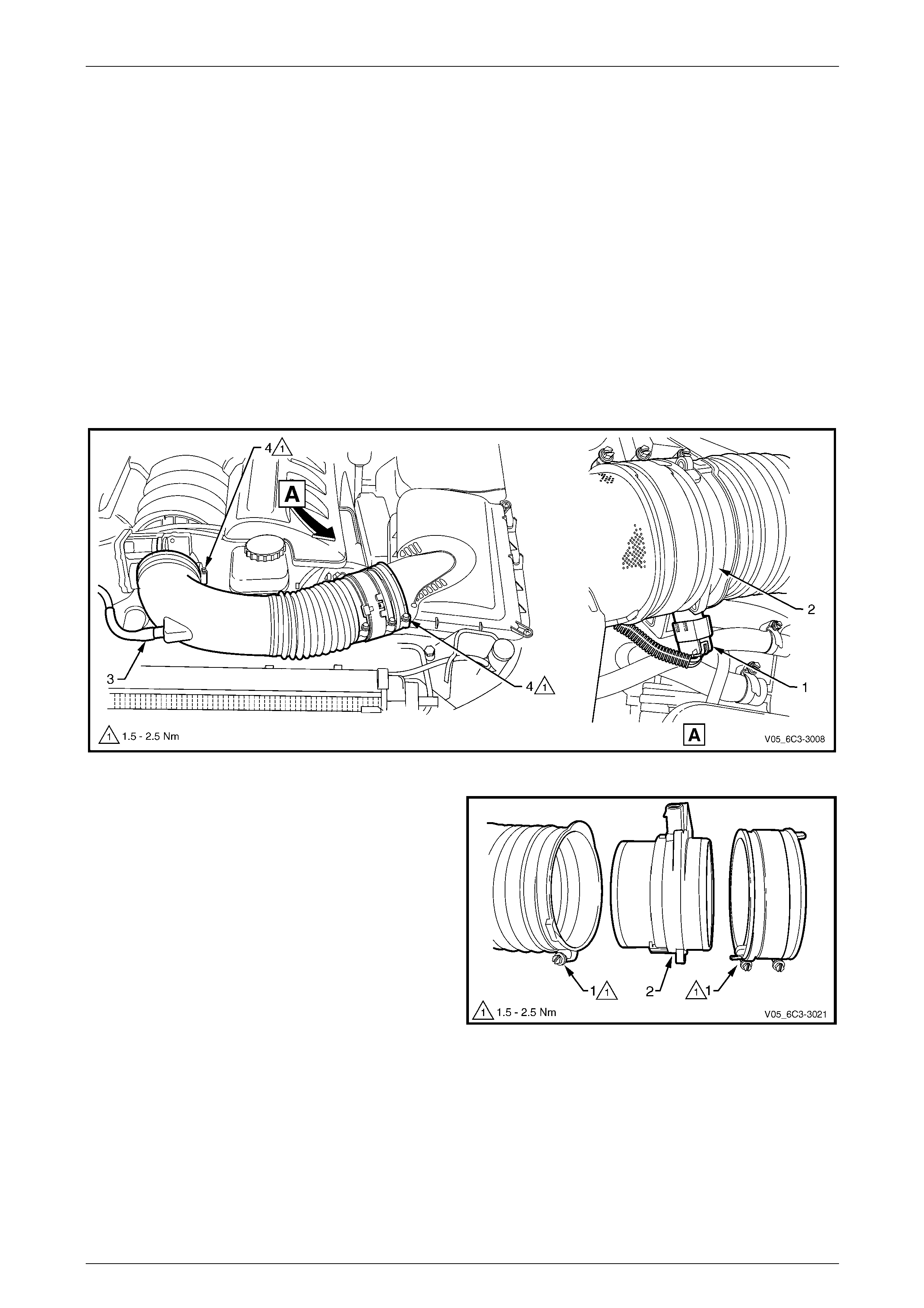

3.17 Mass Air Flow Sensor and Intake Air

Duct

LT Section No. — 03–250

Remove

1 Remove the upper radiator shroud, refer to Section 6B3 Engine Cooling – GEN III V8.

2 Remove the intake air duct:

a Lift up the locking tang on the mass air flow (MAF) sensor wiring connector (1) and remove the connector

from sensor (2).

b Disconnect the PCV hose (3) from the intake air duct.

c Loosen the clamps (4) at each end securing the intake air duct to the throttle body and the air clean er upper

housing. Remove the duct.

Figure 6C3-3 – 37

3 Loosen the two clamps (1) securing the air intake duct

and the air duct adaptor to the MAF sensor (2).

Figure 6C3-3 – 38

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–41

Page 6C3-3–41

Reinstall

Reinstallation of the mass air f low (MAF) sensor and intake air duct is the reverse of the removal proced ure, noting the

following:

NOTE

• The embossed arrows on the MAF sensor

indicate the correct airflow direction. The

arrows must point towards the engine.

• The air duct adaptor (between air cleaner and

MAF sensor), retaining clamps, air duct and

MAF sensor, all have locating notches.

Ensure all notches are aligned.

1 Reinstall the retaining clam ps, aligning the notches, and tighten to the correct torque specification.

Intake air duct clamp

torque specification.....................................1.5 – 2.5 Nm

2 Run the vehicle and check for air leaks.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–42

Page 6C3-3–42

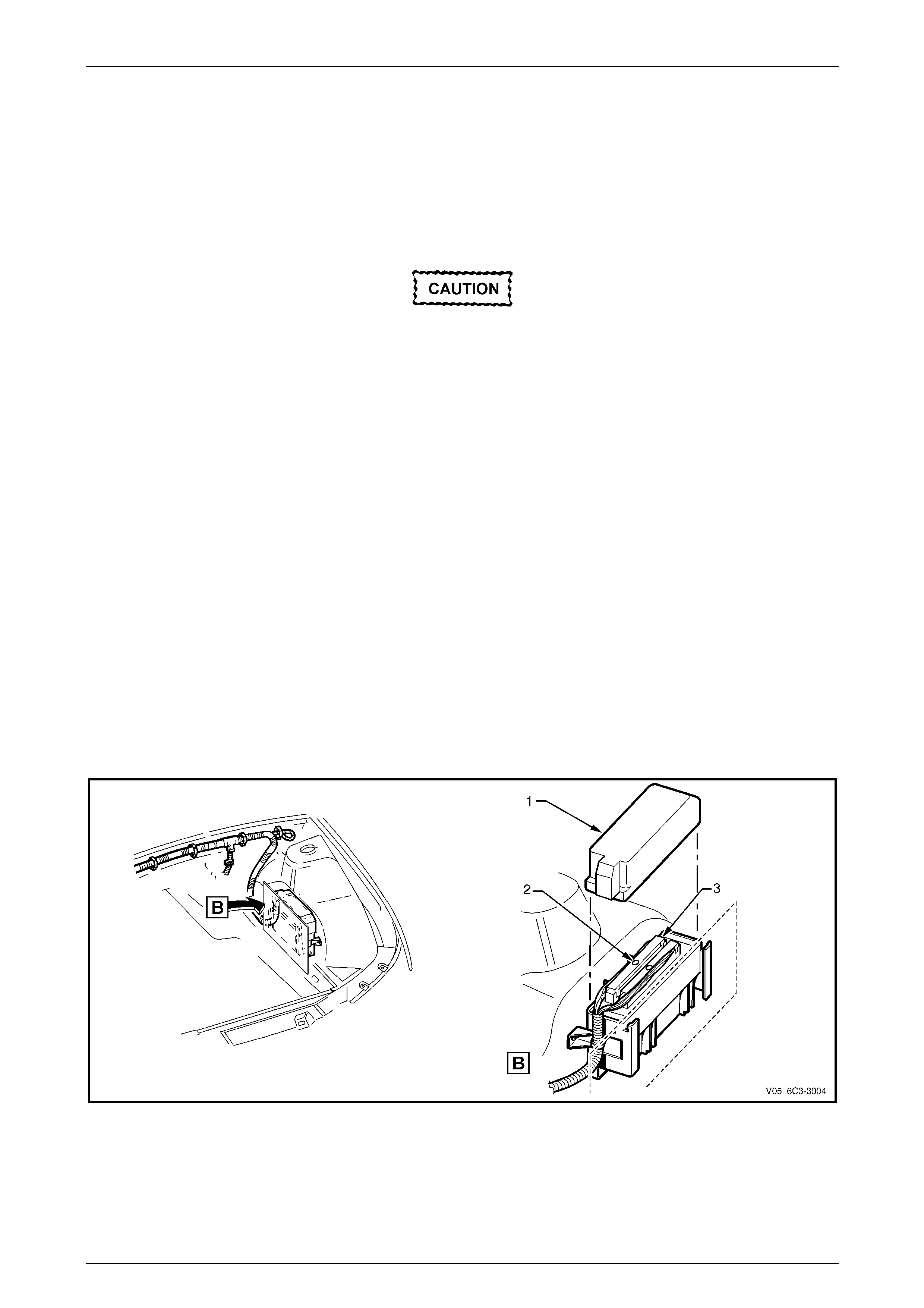

3.18 Powertrain Control Module

LT Section No. — 02–245

Service of the powertrain control modu le (PCM) should normally consist of either replacement or programming. If the

diagnostic procedur es call for the PCM to be replaced, it should be first checked to ensure it is the correct part. If it is,

replace the faulty PCM.

• Do not touch the PCM connector pins as

electrostatic discharge (ESD) damage may

result. For further information on ESD,

refer to Section 00 Warnings, Cautions and

Notes .

• When removing or reinstalling the PCM

wiring connector/s, ensure the ignition

switch is in the OFF position and the

battery has been disconnected. Failure to

do so may result in damage to the PCM

and/or associated components.

• Disconnection of the battery affects

certain vehicle electronic systems. Refer

to Section 00 Warnings, Cautions and

Notes before disconnecting the battery.

Remove

1 Turn the ignition switch off.

2 Disconnect the battery negative lead.

3 Remove the air cleaner assembly, refer to 3.4 Air Cleaner Assembly.

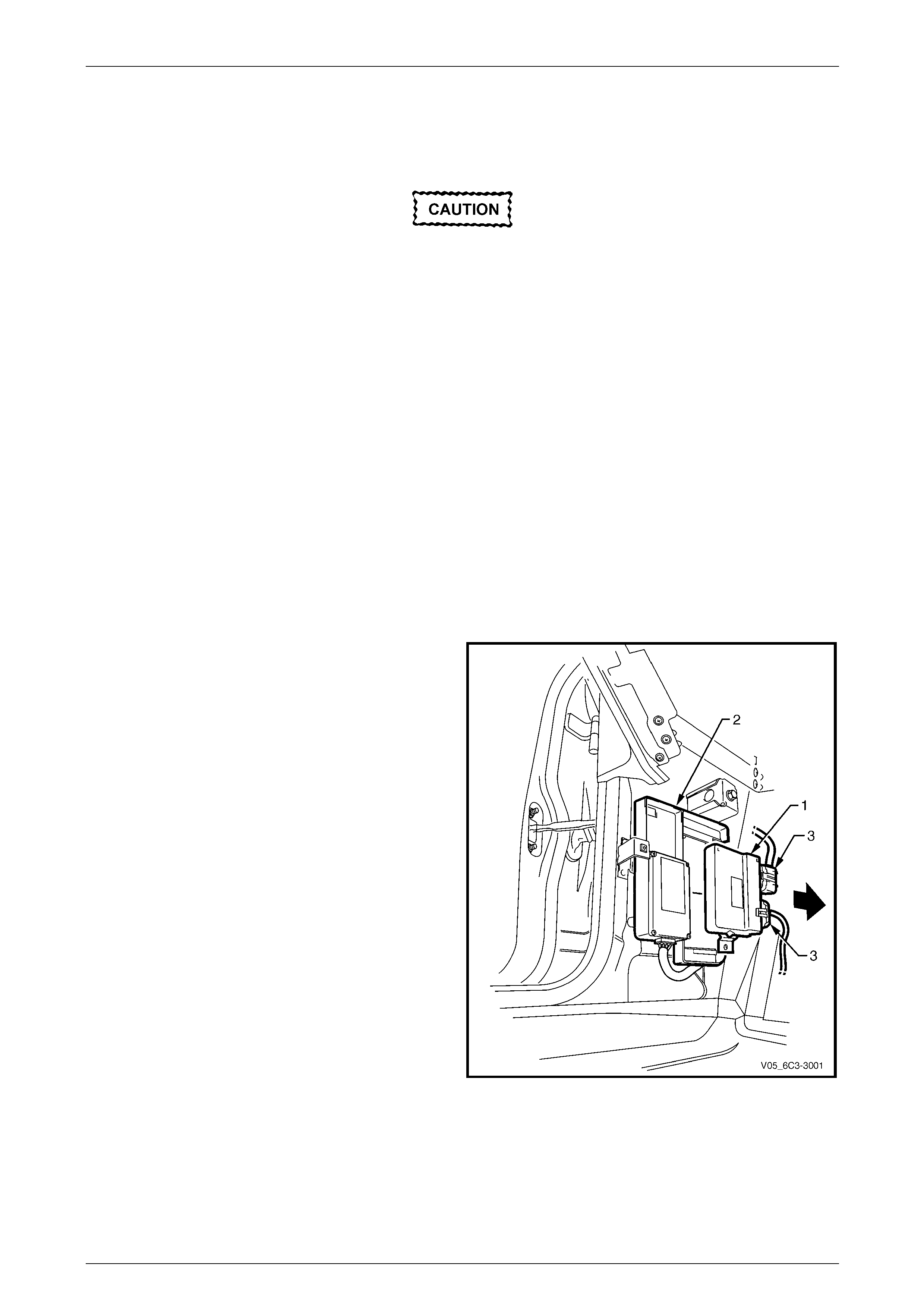

4 Remove PCM wiring connector cover (1).

5 Loosen the connector retaining screw (2) on the PCM wiring connector (3), two places and disconnect the

connectors.

Figure 6C3-3 – 39

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–43

Page 6C3-3–43

6 Lift the PCM (1) from the mounting bracket by levering

back the bracket retainers (2) at each end.

Figure 6C3-3 – 40

Reinstall

Reinstallation of the PCM is the revers e of the removal procedure, noting the following:

1 If the PCM has been replaced, perform the following proced ures:

• PCM service programming, refer to Section 0C Tech 2.

• PCM / PIM / BCM security link, refer to Section 12J Body Control Module.

• Main diagnostic functional check, refer to Section 6C3-2 Powertrain Management – GEN III V8 – Diagnostics.

2 If the PCM has been removed, but not replaced, perform the main diagnostic table functional check,

refer to Section 6C3-2 Powertrain Management – GEN III V8 – Diag nostics.

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–44

Page 6C3-3–44

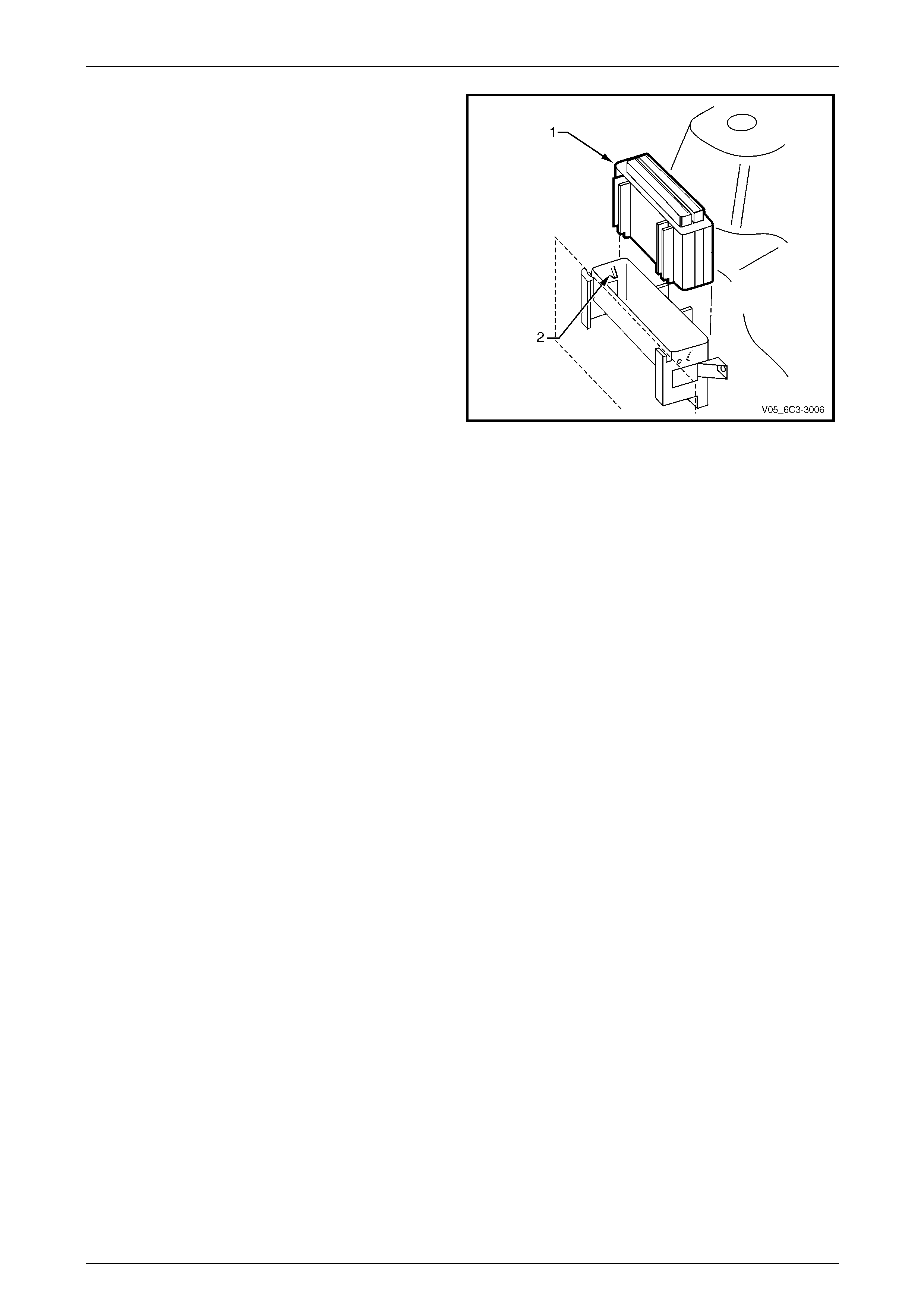

3.19 Powertrain Control Module Bracket

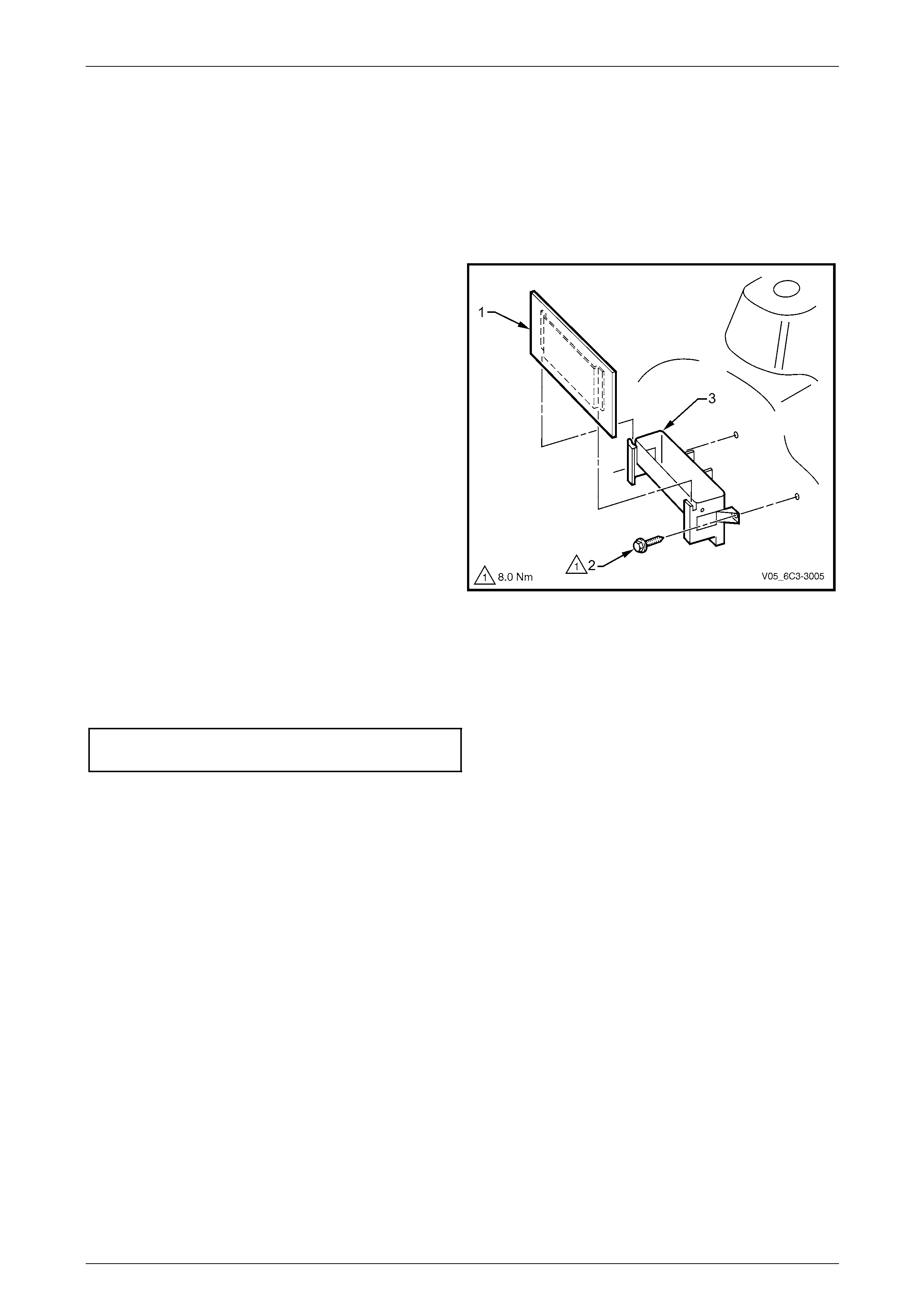

Assembly

LT Section No. — 02–245

Remove

1 Remove the powertrain control module (PCM ), refer to 3.18 Powertrain Control Module.

2 Remove the PCM heat shield (1) by pulling it upwards.

3 Remove the screw (2), two places, attaching the

powertrain control module (PCM) mounting bracket (3)

to the fender inner panel.

4 Remove the mounting bracket from the vehicle.

Figure 6C3-3 – 41

Reinstall

Reinstallation of the powertrain control module (PCM) mounting bracket is the reverse of the removal procedure. Tighten

the screws to the correct torque specification.

Powertrain control module (PCM) mounting

bracket attaching screw torque specification........ 8.0 Nm

Powertrain Management GEN III V8 – Service Operations Page 6C3-3–45

Page 6C3-3–45

3.20 Schrader Valve – Fuel Pressure Test

Point

LT Section No. — XX–XXX

If the Schrader valve is to be removed but not

replaced immediately, it is advisable to

disconnect the battery to avoid possible fuel

discharge if an accidental attempt is made to

start the engine.

Disconnection of the battery affects vehicle

electronic systems. Refer to Section 00

Warnings, Cautions and Notes before

disconnecting the battery.

Remove

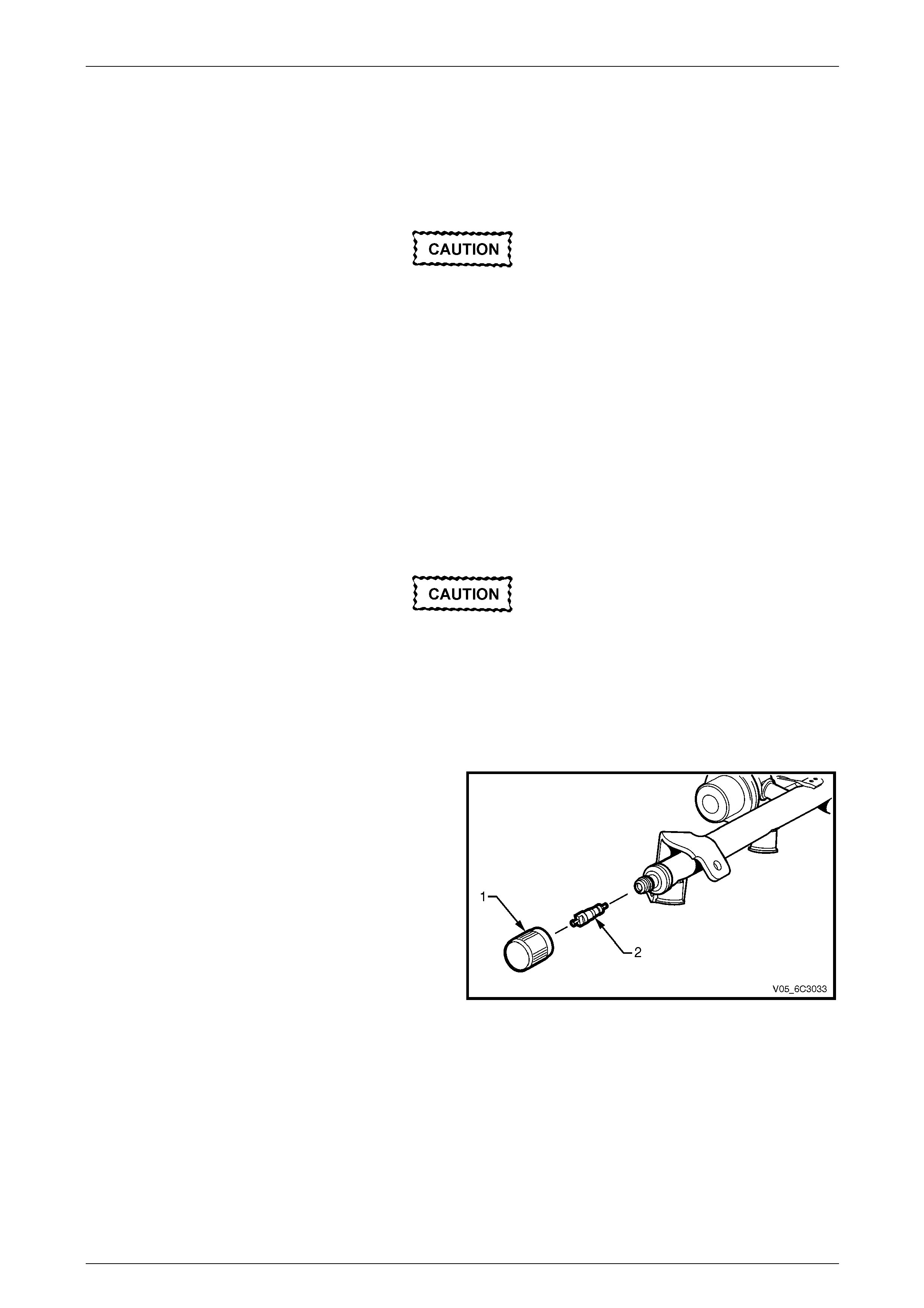

1 Depressurise the fuel system, refer to Section 8A1 Fuel System.

2 Turn the ignition off.

A small amount of fuel may be released when

servicing the fuel pressure test point. To

reduce the chance of personal injury, cover

the fuel pressure test point with a shop towel

to absorb any fuel spillage when the Schrader

valve sealing cap and Schrader valve are

removed. After the pro cedure, place the towel

in an approved container for disposal.

3 Remove the Schrader valve sealing cap (1).

4 Remove the Schrader valve (2) using a stan dard valve

core removal tool.

Figure 6C1-3 – 42

Reinstall

Reinstallation of the Schrader valve is the reverse of the removal procedure, noting th e following:

1 Inspect the fuel rail and quick connect fitting for leaks, refer to Section 8A1 Fuel System.